Page 323 - Buried Pipe Design

P. 323

294 Chapter Six

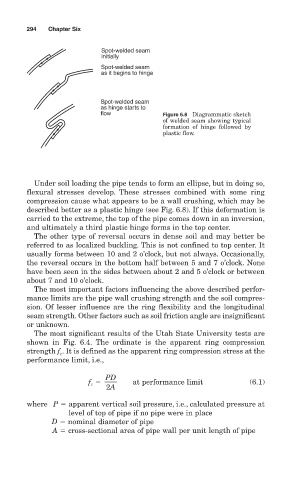

Spot-welded seam

initially

Spot-welded seam

as it begins to hinge

Spot-welded seam

as hinge starts to

flow Figure 6.8 Diagrammatic sketch

of welded seam showing typical

formation of hinge followed by

plastic flow.

Under soil loading the pipe tends to form an ellipse, but in doing so,

flexural stresses develop. These stresses combined with some ring

compression cause what appears to be a wall crushing, which may be

described better as a plastic hinge (see Fig. 6.8). If this deformation is

carried to the extreme, the top of the pipe comes down in an inversion,

and ultimately a third plastic hinge forms in the top center.

The other type of reversal occurs in dense soil and may better be

referred to as localized buckling. This is not confined to top center. It

usually forms between 10 and 2 o’clock, but not always. Occasionally,

the reversal occurs in the bottom half between 5 and 7 o’clock. None

have been seen in the sides between about 2 and 5 o’clock or between

about 7 and 10 o’clock.

The most important factors influencing the above described perfor-

mance limits are the pipe wall crushing strength and the soil compres-

sion. Of lesser influence are the ring flexibility and the longitudinal

seam strength. Other factors such as soil friction angle are insignificant

or unknown.

The most significant results of the Utah State University tests are

shown in Fig. 6.4. The ordinate is the apparent ring compression

strength f . It is defined as the apparent ring compression stress at the

c

performance limit, i.e.,

PD

f c at performance limit (6.1)

2A

where P apparent vertical soil pressure, i.e., calculated pressure at

level of top of pipe if no pipe were in place

D nominal diameter of pipe

A cross-sectional area of pipe wall per unit length of pipe