Page 325 - Buried Pipe Design

P. 325

296 Chapter Six

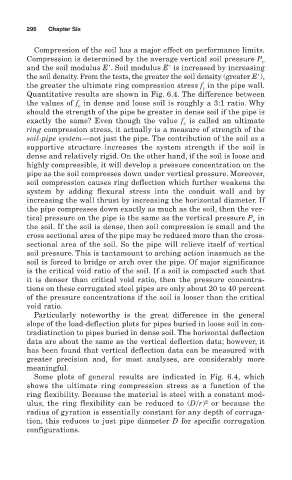

Compression of the soil has a major effect on performance limits.

Compression is determined by the average vertical soil pressure P

v

and the soil modulus E .Soil modulus E is increased by increasing

the soil density. From the tests, the greater the soil density (greater E ),

the greater the ultimate ring compression stress f in the pipe wall.

c

Quantitative results are shown in Fig. 6.4. The difference between

the values of f in dense and loose soil is roughly a 3:1 ratio. Why

c

should the strength of the pipe be greater in dense soil if the pipe is

exactly the same? Even though the value f is called an ultimate

c

ring compression stress, it actually is a measure of strength of the

soil-pipe system—not just the pipe. The contribution of the soil as a

supportive structure increases the system strength if the soil is

dense and relatively rigid. On the other hand, if the soil is loose and

highly compressible, it will develop a pressure concentration on the

pipe as the soil compresses down under vertical pressure. Moreover,

soil compression causes ring deflection which further weakens the

system by adding flexural stress into the conduit wall and by

increasing the wall thrust by increasing the horizontal diameter. If

the pipe compresses down exactly as much as the soil, then the ver-

tical pressure on the pipe is the same as the vertical pressure P in

v

the soil. If the soil is dense, then soil compression is small and the

cross sectional area of the pipe may be reduced more than the cross-

sectional area of the soil. So the pipe will relieve itself of vertical

soil pressure. This is tantamount to arching action inasmuch as the

soil is forced to bridge or arch over the pipe. Of major significance

is the critical void ratio of the soil. If a soil is compacted such that

it is denser than critical void ratio, then the pressure concentra-

tions on these corrugated steel pipes are only about 20 to 40 percent

of the pressure concentrations if the soil is looser than the critical

void ratio.

Particularly noteworthy is the great difference in the general

slope of the load-deflection plots for pipes buried in loose soil in con-

tradistinction to pipes buried in dense soil. The horizontal deflection

data are about the same as the vertical deflection data; however, it

has been found that vertical deflection data can be measured with

greater precision and, for most analyses, are considerably more

meaningful.

Some plots of general results are indicated in Fig. 6.4, which

shows the ultimate ring compression stress as a function of the

ring flexibility. Because the material is steel with a constant mod-

2

ulus, the ring flexibility can be reduced to (D/r) or because the

radius of gyration is essentially constant for any depth of corruga-

tion, this reduces to just pipe diameter D for specific corrugation

configurations.