Page 330 - Buried Pipe Design

P. 330

Steel and Ductile Iron Flexible Pipe Products 301

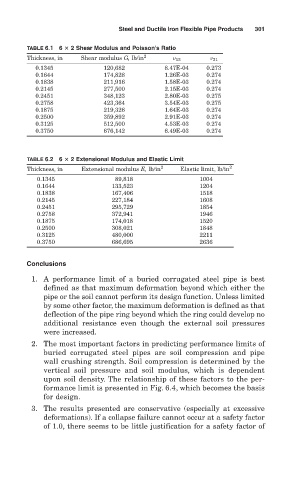

TABLE 6.1 6 2 Shear Modulus and Poisson’s Ratio

Thickness, in Shear modulus G, lb/in 2 12 21

0.1345 120,682 8.47E-04 0.273

0.1644 174,828 1.26E-03 0.274

0.1838 211,916 1.58E-03 0.274

0.2145 277,500 2.15E-03 0.274

0.2451 348,123 2.80E-03 0.275

0.2758 423,364 3.54E-03 0.275

0.1875 219,326 1.64E-03 0.274

0.2500 359,892 2.91E-03 0.274

0.3125 512,500 4.53E-03 0.274

0.3750 676,142 6.49E-03 0.274

TABLE 6.2 6 2 Extensional Modulus and Elastic Limit

Thickness, in Extensional modulus E, lb/in 2 Elastic limit, lb/in 2

0.1345 89,818 1004

0.1644 133,523 1204

0.1838 167,406 1518

0.2145 227,184 1608

0.2451 295,729 1854

0.2758 372,941 1946

0.1875 174,018 1520

0.2500 308,021 1848

0.3125 480,000 2211

0.3750 686,695 2636

Conclusions

1. A performance limit of a buried corrugated steel pipe is best

defined as that maximum deformation beyond which either the

pipe or the soil cannot perform its design function. Unless limited

by some other factor, the maximum deformation is defined as that

deflection of the pipe ring beyond which the ring could develop no

additional resistance even though the external soil pressures

were increased.

2. The most important factors in predicting performance limits of

buried corrugated steel pipes are soil compression and pipe

wall crushing strength. Soil compression is determined by the

vertical soil pressure and soil modulus, which is dependent

upon soil density. The relationship of these factors to the per-

formance limit is presented in Fig. 6.4, which becomes the basis

for design.

3. The results presented are conservative (especially at excessive

deformations). If a collapse failure cannot occur at a safety factor

of 1.0, there seems to be little justification for a safety factor of