Page 336 - Buried Pipe Design

P. 336

Steel and Ductile Iron Flexible Pipe Products 307

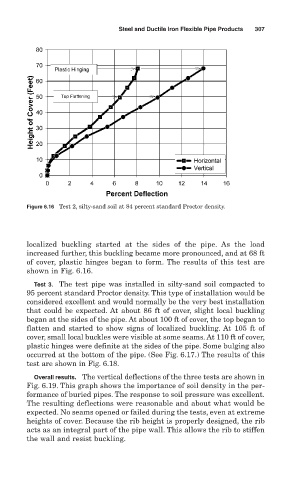

Figure 6.16 Test 2, silty-sand soil at 84 percent standard Proctor density.

localized buckling started at the sides of the pipe. As the load

increased further, this buckling became more pronounced, and at 68 ft

of cover, plastic hinges began to form. The results of this test are

shown in Fig. 6.16.

Test 3. The test pipe was installed in silty-sand soil compacted to

95 percent standard Proctor density. This type of installation would be

considered excellent and would normally be the very best installation

that could be expected. At about 86 ft of cover, slight local buckling

began at the sides of the pipe. At about 100 ft of cover, the top began to

flatten and started to show signs of localized buckling. At 105 ft of

cover, small local buckles were visible at some seams. At 110 ft of cover,

plastic hinges were definite at the sides of the pipe. Some bulging also

occurred at the bottom of the pipe. (See Fig. 6.17.) The results of this

test are shown in Fig. 6.18.

Overall results. The vertical deflections of the three tests are shown in

Fig. 6.19. This graph shows the importance of soil density in the per-

formance of buried pipes. The response to soil pressure was excellent.

The resulting deflections were reasonable and about what would be

expected. No seams opened or failed during the tests, even at extreme

heights of cover. Because the rib height is properly designed, the rib

acts as an integral part of the pipe wall. This allows the rib to stiffen

the wall and resist buckling.