Page 338 - Buried Pipe Design

P. 338

Steel and Ductile Iron Flexible Pipe Products 309

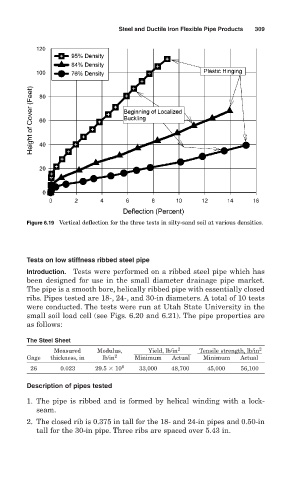

Figure 6.19 Vertical deflection for the three tests in silty-sand soil at various densities.

Tests on low stiffness ribbed steel pipe

Introduction. Tests were performed on a ribbed steel pipe which has

been designed for use in the small diameter drainage pipe market.

The pipe is a smooth bore, helically ribbed pipe with essentially closed

ribs. Pipes tested are 18-, 24-, and 30-in diameters. A total of 10 tests

were conducted. The tests were run at Utah State University in the

small soil load cell (see Figs. 6.20 and 6.21). The pipe properties are

as follows:

The Steel Sheet

Measured Modulus, Yield, lb/in 2 Tensile strength, lb/in 2

Gage thickness, in lb/in 2 Minimum Actual Minimum Actual

26 0.023 29.5 10 6 33,000 48,700 45,000 56,100

Description of pipes tested

1. The pipe is ribbed and is formed by helical winding with a lock-

seam.

2. The closed rib is 0.375 in tall for the 18- and 24-in pipes and 0.50-in

tall for the 30-in pipe. Three ribs are spaced over 5.43 in.