Page 82 - CNC Robotics

P. 82

Chapter 2 / Electronics

APPLICATION NOTE

plemented directly using the l297 or L6506. In the comparator.The current cont rol circuit is com-

this mode, ignoring back EMF. the voltage across pletely content to keep operating in this condition.

the coil during the on time (11) when current is in- In fact the circuit may ope rate on one of two sta-

creasing and the recirculation time (12), are: ble conditions depending on the random time

V, = Vs · 2 Vsat • VRsense when the peak curre nt is first reached relative to

the oscillator period.

and

The easiest, and recommended, solution is to ap-

Vz = Vss + 2 VF ply the chopping signal to only one of the phase

The rate of current change is given by (ignoring inputs, as imple mented with the L297, In the

the series resistance): phase chopping mode, or the L6506.

Another solution that works, in some cases, is to

V = L.9.i fix a large minimum duty cycle, in the range of

dt

30%, by applying an external clock signal to the

sync input of the L297 or L6506. In th is configura-

Since the voltage across the coil (V2) durin g the tion the circuit must output at least the rninimrm

recirculation time is more than the voltage (V,) duty cycle during each clock period. This forces

across the coil during the on lime the duty cycle the point where the peak current is detected to be

will, by definition, be greater tha n 50% because 11 later in each cycle and the chopping frequency to

must be greater than 12. When the back EMF 01 lock on the fundamental. The main disadvantage

the motor is considered the duty cycle becomes of this approach is that it sets a higher minirru m

even greater since the back EMF opposes the in- current that can be controlled . The current in the

crease of current during the on time and aides the motor also tends to overshoot during the first few

decay of current. chopping cycles since the actual peak current is

In this conclitionthe control circuit may be content not be sensed during the minimum duty cycle.

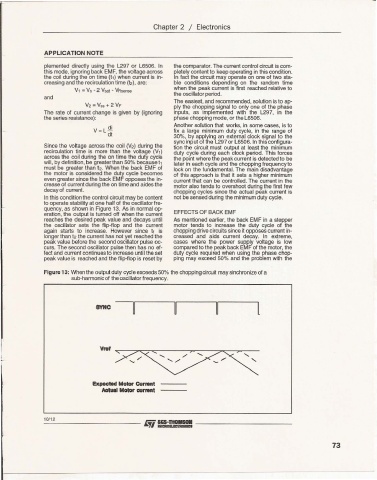

to ope rate stability at one half of the oscillator fre-

que ncy, as shown in Figure 13. As in normal op-

eration, the output is turned off when the cur rent EFFECTS OF BACK EMF

reaches the desired peak value and decays until As ment ioned earlier, the back EMF in a stepper

the oscillator sets the flip-flop and the current motor tends to increase the duty cycl e of the

again starts to increase. However since t1 is chopping drive circuits since it opposes current in-

longer than t2 the current has not yet reached the creased and aids current decay. In extreme,

peak value before the seco nd oscillator pulse oc- cases where the power supply voltage is low

curs. The second oscillator pulse then has no ef- compared to the peak back EMF of the motor, the

fect and current continues to increase until the set duty cycle required when using the phase chop-

peak value is reached and the flip-flop is reset by ping may exceed 50% and the problem with the

Figure 13: When the output duty cycle exceeds 50% the chopping circuit may sinchronize of a

sub-harmonic of the oscillator frequency.

l

Expected Molor c..,....t

Actual Motor current

10112

73