Page 317 - Cam Design Handbook

P. 317

THB10 9/19/03 7:28 PM Page 305

CAM MANUFACTURING 305

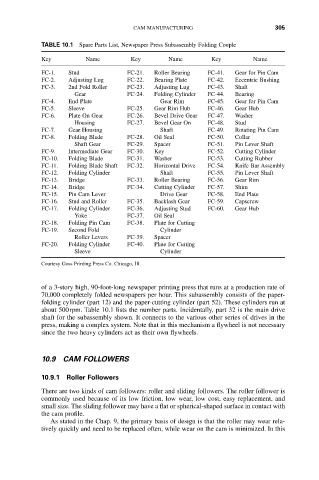

TABLE 10.1 Spare Parts List, Newspaper Press Subassembly Folding Couple

Key Name Key Name Key Name

FC-1. Stud FC-21. Roller Bearing FC-41. Gear for Pin Cam

FC-2. Adjusting Lug FC-22. Bearing Plate FC-42. Eccentric Bushing

FC-3. 2nd Fold Roller FC-23. Adjusting Lug FC-43. Shaft

Gear FC-24. Folding Cylinder FC-44. Bearing

FC-4. End Plate Gear Rim FC-45. Gear for Pin Cam

FC-5. Sleeve FC-25. Gear Rim Hub FC-46. Gear Hub

FC-6. Plate On Gear FC-26. Bevel Drive Gear FC-47. Washer

Housing FC-27. Bevel Gear On FC-48. Stud

FC-7. Gear Housing Shaft FC-49. Rotating Pin Cam

FC-8. Folding Blade FC-28. Oil Seal FC-50. Collar

Shaft Gear FC-29. Spacer FC-51. Pin Lever Shaft

FC-9. Intermediate Gear FC-30. Key FC-52. Cutting Cylinder

FC-10. Folding Blade FC-31. Washer FC-53. Cutting Rubber

FC-11. Folding Blade Shaft FC-32. Horizontal Drive FC-54. Knife Bar Assembly

FC-12. Folding Cylinder Shaft FC-55. Pin Lever Shaft

FC-13. Bridge FC-33. Roller Bearing FC-56. Gear Rim

FC-14. Bridge FC-34. Cutting Cylinder FC-57. Shim

FC-15. Pin Cam Lever Drive Gear FC-58. End Plate

FC-16. Stud and Roller FC-35. Backlash Gear FC-59. Capscrew

FC-17. Folding Cylinder FC-36. Adjusting Stud FC-60. Gear Hub

Yoke FC-37. Oil Seal

FC-18. Folding Pin Cam FC-38. Plate for Cutting

FC-19. Second Fold Cylinder

Roller Levers FC-39. Spacer

FC-20. Folding Cylinder FC-40. Plate for Cutting

Sleeve Cylinder

Courtesy Goss Printing Press Co. Chicago, Ill.

of a 3-story high, 90-foot-long newspaper printing press that runs at a production rate of

70,000 completely folded newspapers per hour. This subassembly consists of the paper-

folding cylinder (part 12) and the paper-cutting cylinder (part 52). These cylinders run at

about 500rpm. Table 10.1 lists the number parts. Incidentally, part 32 is the main drive

shaft for the subassembly shown. It connects to the various other series of drives in the

press, making a complex system. Note that in this mechanism a flywheel is not necessary

since the two heavy cylinders act as their own flywheels.

10.9 CAM FOLLOWERS

10.9.1 Roller Followers

There are two kinds of cam followers: roller and sliding followers. The roller follower is

commonly used because of its low friction, low wear, low cost, easy replacement, and

small size. The sliding follower may have a flat or spherical-shaped surface in contact with

the cam profile.

As stated in the Chap. 9, the primary basis of design is that the roller may wear rela-

tively quickly and need to be replaced often, while wear on the cam is minimized. In this