Page 320 - Cam Design Handbook

P. 320

THB10 9/19/03 7:28 PM Page 308

308 CAM DESIGN HANDBOOK

Load

Stress

Stress

Cam

(a) Straight roller. (b) Crowned roller.

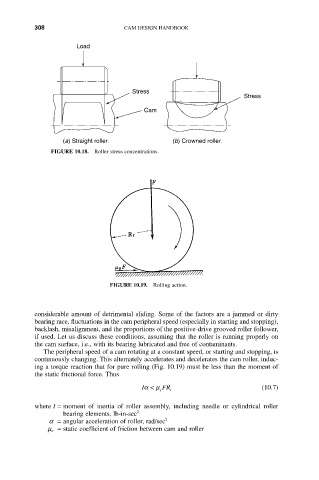

FIGURE 10.18. Roller stress concentrations.

FIGURE 10.19. Rolling action.

considerable amount of detrimental sliding. Some of the factors are a jammed or dirty

bearing race, fluctuations in the cam peripheral speed (especially in starting and stopping),

backlash, misalignment, and the proportions of the positive-drive grooved roller follower,

if used. Let us discuss these conditions, assuming that the roller is running properly on

the cam surface, i.e., with its bearing lubricated and free of contaminants.

The peripheral speed of a cam rotating at a constant speed, or starting and stopping, is

continuously changing. This alternately accelerates and decelerates the cam roller, induc-

ing a torque reaction that for pure rolling (Fig. 10.19) must be less than the moment of

the static frictional force. Thus

Ia < m s FR r (10.7)

where I = moment of inertia of roller assembly, including needle or cylindrical roller

bearing elements, lb-in-sec 2

a = angular acceleration of roller, rad/sec 2

m s = static coefficient of friction between cam and roller