Page 313 - Cam Design Handbook

P. 313

THB10 9/19/03 7:28 PM Page 301

CAM MANUFACTURING 301

Actual measured

and calculated by

finite differences

Acceleration

Theoretical cycloidal

cam curve

(a)

b (b)

3

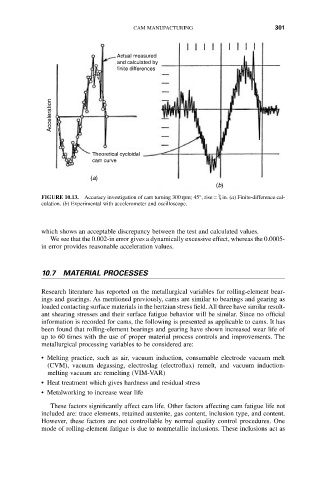

FIGURE 10.13. Accuracy investigation of cam turning 300rpm; 45°, rise = / 4 in. (a) Finite-difference cal-

culation. (b) Experimental with accelerometer and oscilloscope.

which shows an acceptable discrepancy between the test and calculated values.

We see that the 0.002-in error gives a dynamically excessive effect, whereas the 0.0005-

in error provides reasonable acceleration values.

10.7 MATERIAL PROCESSES

Research literature has reported on the metallurgical variables for rolling-element bear-

ings and gearings. As mentioned previously, cams are similar to bearings and gearing as

loaded contacting surface materials in the hertzian stress field. All three have similar result-

ant shearing stresses and their surface fatigue behavior will be similar. Since no official

information is recorded for cams, the following is presented as applicable to cams. It has

been found that rolling-element bearings and gearing have shown increased wear life of

up to 60 times with the use of proper material process controls and improvements. The

metallurgical processing variables to be considered are:

• Melting practice, such as air, vacuum induction, consumable electrode vacuum melt

(CVM), vacuum degassing, electroslag (electroflux) remelt, and vacuum induction-

melting vacuum arc remelting (VIM-VAR)

• Heat treatment which gives hardness and residual stress

• Metalworking to increase wear life

These factors significantly affect cam life. Other factors affecting cam fatigue life not

included are: trace elements, retained austenite, gas content, inclusion type, and content.

However, these factors are not controllable by normal quality control procedures. One

mode of rolling-element fatigue is due to nonmetallic inclusions. These inclusions act as