Page 465 - Cam Design Handbook

P. 465

THB14 9/19/03 7:58 PM Page 453

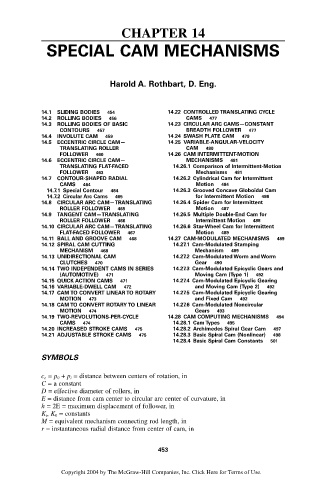

CHAPTER 14

SPECIAL CAM MECHANISMS

Harold A. Rothbart, D. Eng.

14.1 SLIDING BODIES 454 14.22 CONTROLLED TRANSLATING CYCLE

14.2 ROLLING BODIES 456 CAMS 477

14.3 ROLLING BODIES OF BASIC 14.23 CIRCULAR ARC CAMS—CONSTANT

CONTOURS 457 BREADTH FOLLOWER 477

14.4 INVOLUTE CAM 459 14.24 SWASH PLATE CAM 479

14.5 ECCENTRIC CIRCLE CAM— 14.25 VARIABLE-ANGULAR-VELOCITY

TRANSLATING ROLLER CAM 480

FOLLOWER 460 14.26 CAM INTERMITTENT-MOTION

14.6 ECCENTRIC CIRCLE CAM— MECHANISMS 481

TRANSLATING FLAT-FACED 14.26.1 Comparison of Intermittent-Motion

FOLLOWER 463 Mechanisms 481

14.7 CONTOUR-SHAPED RADIAL 14.26.2 Cylindrical Cam for Intermittent

CAMS 464 Motion 484

14.7.1 Special Contour 464 14.26.3 Grooved Concave Globoidal Cam

14.7.2 Circular Arc Cams 465 for Intermittent Motion 486

14.8 CIRCULAR ARC CAM—TRANSLATING 14.26.4 Spider Cam for Intermittent

ROLLER FOLLOWER 465 Motion 487

14.9 TANGENT CAM—TRANSLATING 14.26.5 Multiple Double-End Cam for

ROLLER FOLLOWER 466 Intermittent Motion 488

14.10 CIRCULAR ARC CAM—TRANSLATING 14.26.6 Star-Wheel Cam for Intermittent

FLAT-FACED FOLLOWER 467 Motion 489

14.11 BALL AND GROOVE CAM 468 14.27 CAM-MODULATED MECHANISMS 489

14.12 SPIRAL CAM CUTTING 14.27.1 Cam-Modulated Stamping

MECHANISM 468 Mechanism 489

14.13 UNIDIRECTIONAL CAM 14.27.2 Cam-Modulated Worm and Worm

CLUTCHES 470 Gear 490

14.14 TWO INDEPENDENT CAMS IN SERIES 14.27.3 Cam-Modulated Epicyclic Gears and

(AUTOMOTIVE) 471 Moving Cam (Type 1) 492

14.15 QUICK ACTION CAMS 471 14.27.4 Cam-Modulated Epicyclic Gearing

14.16 VARIABLE-DWELL CAM 472 and Moving Cam (Type 2) 492

14.17 CAM TO CONVERT LINEAR TO ROTARY 14.27.5 Cam-Modulated Epicyclic Gearing

MOTION 473 and Fixed Cam 492

14.18 CAM TO CONVERT ROTARY TO LINEAR 14.27.6 Cam-Modulated Noncircular

MOTION 474 Gears 493

14.19 TWO-REVOLUTIONS-PER-CYCLE 14.28 CAM COMPUTING MECHANISMS 494

CAMS 474 14.28.1 Cam Types 495

14.20 INCREASED STROKE CAMS 475 14.28.2 Archimedes Spiral Gear Cam 497

14.21 ADJUSTABLE STROKE CAMS 475 14.28.3 Basic Spiral Cam (Nonlinear) 498

14.28.4 Basic Spiral Cam Constants 501

SYMBOLS

c e = p 0 + p i = distance between centers of rotation, in

C = a constant

D = effective diameter of rollers, in

E = distance from cam center to circular arc center of curvature, in

h = 2E = maximum displacement of follower, in

K i, K 0 = constants

M = equivalent mechanism connecting rod length, in

r = instantaneous radial distance from center of cam, in

453

Copyright 2004 by The McGraw-Hill Companies, Inc. Click Here for Terms of Use.