Page 500 - Cam Design Handbook

P. 500

THB14 9/19/03 7:58 PM Page 488

488 CAM DESIGN HANDBOOK

14.26.5 Multiple Double-End Cam for Intermittent Motion

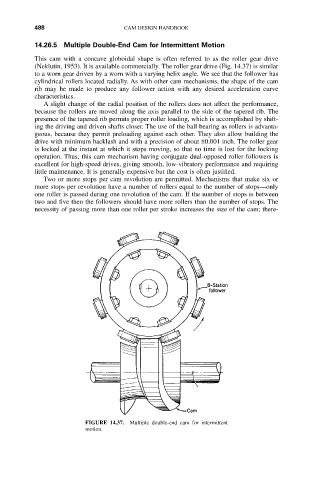

This cam with a concave globoidal shape is often referred to as the roller gear drive

(Neklutin, 1953). It is available commercially. The roller gear drive (Fig. 14.37) is similar

to a worn gear driven by a worn with a varying helix angle. We see that the follower has

cylindrical rollers located radially. As with other cam mechanisms, the shape of the cam

rib may be made to produce any follower action with any desired acceleration curve

characteristics.

A slight change of the radial position of the rollers does not affect the performance,

because the rollers are moved along the axis parallel to the side of the tapered rib. The

presence of the tapered rib permits proper roller loading, which is accomplished by shift-

ing the driving and driven shafts closer. The use of the ball bearing as rollers is advanta-

geous, because they permit preloading against each other. They also allow building the

drive with minimum backlash and with a precision of about ±0.001 inch. The roller gear

is locked at the instant at which it stops moving, so that no time is lost for the locking

operation. Thus, this cam mechanism having conjugate dual-opposed roller followers is

excellent for high-speed drives, giving smooth, low-vibratory performance and requiring

little maintenance. It is generally expensive but the cost is often justified.

Two or more stops per cam revolution are permitted. Mechanisms that make six or

more stops per revolution have a number of rollers equal to the number of stops—only

one roller is passed during one revolution of the cam. If the number of stops is between

two and five then the followers should have more rollers than the number of stops. The

necessity of passing more than one roller per stroke increases the size of the cam; there-

FIGURE 14.37. Multiple double-end cam for intermittent

motion.