Page 297 - Carbon Nanotube Fibres and Yarns

P. 297

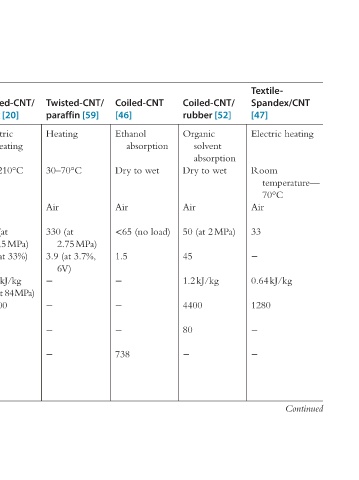

Textile- Spandex/CNT [47] Electric heating Room temperature— 70°C Air 33 − 0.64 kJ/kg 1280 − − Continued

Coiled-CNT/ rubber [52] Organic solvent absorption Dry to wet Air 50 (at 2 MPa) 45 1.2 kJ/kg 4400 80 −

Coiled-CNT [46] Ethanol absorption Dry to wet Air <65 (no load) 1.5 − − − 738

Twisted-CNT/ paraffin [59] Heating 30–70°C Air 330 (at 2.75 MPa) 3.9 (at 3.7%, V) 6 − − − −

Coiled-CNT/ wax [20] Electric heating 80–210°C Air 9.5 (at 5.5 MPa) 84 (at 33%) 1.36 kJ/kg (at 84 MPa) 27900 120 16

Coiled-CNT [58] Electrochemistry 3.25 Electrolyte 16.5 (at 25 MPa) 60 (at 4.5%) 2.2 kJ/kg <15 ≪1 −

Examples of CNT yarn-based actuators [46]. Twisted-CNT Twisted-CNT [44] Electrochemistry Electricity V 2 0–5mA Electrolyte Air, olvents, electrolyte 1 (at 88 MPa) 88 (at 1%) 1.1 kJ/kg >430 kJ/m 3 920 1 250

Table 11.1 [49] Property Stimulus Amplitude of stimulus Media 2 Output Strain (%) 10 Output Stress (MPa) Work density − Power density (W/kg) − Output strain rate (%/s) − T orsional stroke (degree/ mm)