Page 300 - Carbon Nanotube Fibres and Yarns

P. 300

Carbon nanotube yarn-based actuators 287

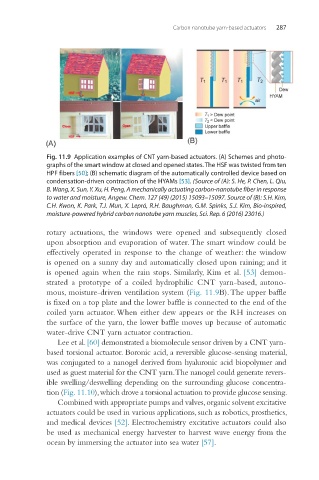

Fig. 11.9 Application examples of CNT yarn-based actuators. (A) Schemes and photo-

graphs of the smart window at closed and opened states. The HSF was twisted from ten

HPF fibers [50]; (B) schematic diagram of the automatically controlled device based on

condensation-driven contraction of the HYAMs [53]. (Source of (A): S. He, P. Chen, L. Qiu,

B. Wang, X. Sun, Y. Xu, H. Peng, A mechanically actuating carbon-nanotube fiber in response

to water and moisture, Angew. Chem. 127 (49) (2015) 15093–15097. Source of (B): S.H. Kim,

C.H. Kwon, K. Park, T.J. Mun, X. Lepró, R.H. Baughman, G.M. Spinks, S.J. Kim, Bio-inspired,

moisture- powered hybrid carbon nanotube yarn muscles, Sci. Rep. 6 (2016) 23016.)

rotary actuations, the windows were opened and subsequently closed

upon absorption and evaporation of water. The smart window could be

effectively operated in response to the change of weather: the window

is opened on a sunny day and automatically closed upon raining; and it

is opened again when the rain stops. Similarly, Kim et al. [53] demon-

strated a prototype of a coiled hydrophilic CNT yarn-based, autono-

mous, moisture-driven ventilation system (Fig. 11.9B). The upper baffle

is fixed on a top plate and the lower baffle is connected to the end of the

coiled yarn actuator. When either dew appears or the RH increases on

the surface of the yarn, the lower baffle moves up because of automatic

water-drive CNT yarn actuator contraction.

Lee et al. [60] demonstrated a biomolecule sensor driven by a CNT yarn-

based torsional actuator. Boronic acid, a reversible glucose-sensing material,

was conjugated to a nanogel derived from hyaluronic acid biopolymer and

used as guest material for the CNT yarn. The nanogel could generate revers-

ible swelling/deswelling depending on the surrounding glucose concentra-

tion (Fig. 11.10), which drove a torsional actuation to provide glucose sensing.

Combined with appropriate pumps and valves, organic solvent excitative

actuators could be used in various applications, such as robotics, prosthetics,

and medical devices [52]. Electrochemistry excitative actuators could also

be used as mechanical energy harvester to harvest wave energy from the

ocean by immersing the actuator into sea water [57].