Page 38 - Carbon Nanotube Fibres and Yarns

P. 38

Yarn production from carbon nanotube forests 31

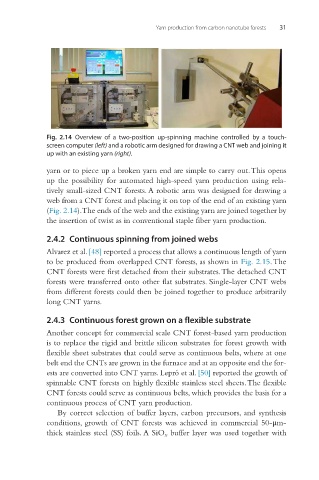

Fig. 2.14 Overview of a two-position up-spinning machine controlled by a touch-

screen computer (left) and a robotic arm designed for drawing a CNT web and joining it

up with an existing yarn (right).

yarn or to piece up a broken yarn end are simple to carry out. This opens

up the possibility for automated high-speed yarn production using rela-

tively small-sized CNT forests. A robotic arm was designed for drawing a

web from a CNT forest and placing it on top of the end of an existing yarn

(Fig. 2.14). The ends of the web and the existing yarn are joined together by

the insertion of twist as in conventional staple fiber yarn production.

2.4.2 Continuous spinning from joined webs

Alvarez et al. [48] reported a process that allows a continuous length of yarn

to be produced from overlapped CNT forests, as shown in Fig. 2.15. The

CNT forests were first detached from their substrates. The detached CNT

forests were transferred onto other flat substrates. Single-layer CNT webs

from different forests could then be joined together to produce arbitrarily

long CNT yarns.

2.4.3 Continuous forest grown on a flexible substrate

Another concept for commercial scale CNT forest-based yarn production

is to replace the rigid and brittle silicon substrates for forest growth with

flexible sheet substrates that could serve as continuous belts, where at one

belt end the CNTs are grown in the furnace and at an opposite end the for-

ests are converted into CNT yarns. Lepró et al. [50] reported the growth of

spinnable CNT forests on highly flexible stainless steel sheets. The flexible

CNT forests could serve as continuous belts, which provides the basis for a

continuous process of CNT yarn production.

By correct selection of buffer layers, carbon precursors, and synthesis

conditions, growth of CNT forests was achieved in commercial 50-μm-

thick stainless steel (SS) foils. A SiO x buffer layer was used together with