Page 34 - Carbon Nanotube Fibres and Yarns

P. 34

Yarn production from carbon nanotube forests 27

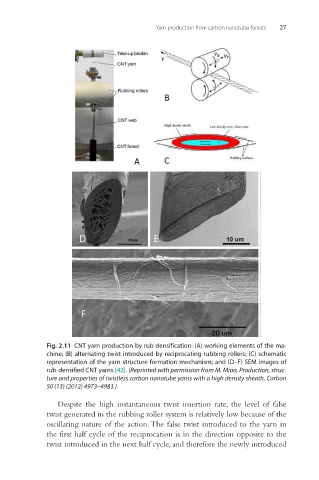

Fig. 2.11 CNT yarn production by rub densification: (A) working elements of the ma-

chine; (B) alternating twist introduced by reciprocating rubbing rollers; (C) schematic

representation of the yarn structure formation mechanism; and (D–F) SEM images of

rub-densified CNT yarns [42]. (Reprinted with permission from M. Miao, Production, struc-

ture and properties of twistless carbon nanotube yarns with a high density sheath, Carbon

50 (13) (2012) 4973–4983.)

Despite the high instantaneous twist insertion rate, the level of false

twist generated in the rubbing roller system is relatively low because of the

oscillating nature of the action. The false twist introduced to the yarn in

the first half cycle of the reciprocation is in the direction opposite to the

twist introduced in the next half cycle, and therefore the newly introduced