Page 56 - Carbon Nanotube Fibres and Yarns

P. 56

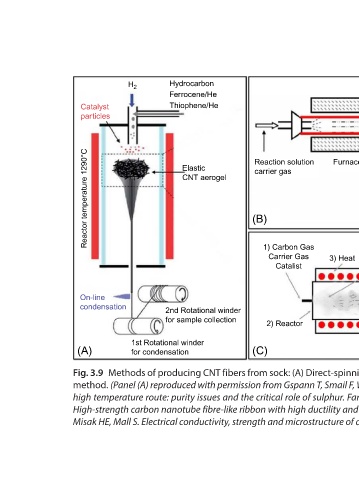

Methods of producing CNT fibers from sock: (A) Direct-spinning method. (B) Bath-spinning method. (C) Rotating-anchor spinning

method. (Panel (A) reproduced with permission from Gspann T, Smail F, Windle A. Spinning of carbon nanotube fibres using the floating catalyst

Winding

system

9) Bobbin

8) CNT-Yarn

Misak HE, Mall S. Electrical conductivity, strength and microstructure of carbon nanotube multi-yarns. Mater. Des. 75 (2015) 76–84.)

CNT fiber

7) CNT Arrays

6) Rotating anchor

5) Aerogel

4) CNTs

Furnace Hollow Ceramic tube cylindrical CNT assembly Water or alcohol Container Carbon nanotube fibers spun directly from furnace high temperature route: purity issues and the critical role of sulphur. Faraday Discuss. 173 (2014) 2–7, (B) from Wang JN, Luo XG, Wu T, Chen Y. High-strength carbon nanotube

3) Heat

Reaction solution carrier gas (B) 1) Carbon Gas Carrier Gas Catalist 2) Reactor (C)

Hydrocarbon Ferrocene/He Thiophene/He Elastic CNT aerogel 2nd Rotational winder for sample collection 1st Rotational winder

H 2 for condensation

Catalyst particles Reactor temperature 1290°C On-line condensation (A) Fig. 3.9