Page 53 - Carbon Nanotube Fibres and Yarns

P. 53

46 Carbon Nanotube Fibers and Yarns

increase in CNT quality to mask the influence of the amorphous impuri-

ties. The I G /I D ratio increases by almost more than 200%, from 1150°C to

1500°C. This shows that CNTs of better quality with fewer defects can be

obtained at higher temperatures.

3.3 CNT assembly and fiber production

CNTs synthesized by floating catalyst method could be transformed into

different macro assemblies. They can form unorganized entities, such as clus-

ters or powders on the reactor wall or a collector [50], or alternatively CNTs

from an aerosol that can be deposited on various substrates as thin films [51].

Meanwhile, these gas-carried CNTs can be assembled into organized entities,

such as CNT array on a substrate placed inside the reactor [23, 38, 40, 41].

More importantly, an aerogel-like sock structure could be formed at relatively

high temperature, which can easily be transformed into a CNT fiber [37, 52].

3.3.1 CNT sock

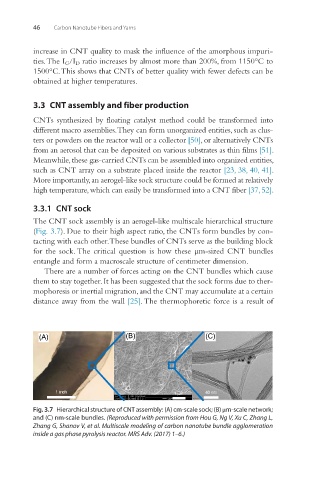

The CNT sock assembly is an aerogel-like multiscale hierarchical structure

(Fig. 3.7). Due to their high aspect ratio, the CNTs form bundles by con-

tacting with each other. These bundles of CNTs serve as the building block

for the sock. The critical question is how these μm-sized CNT bundles

entangle and form a macroscale structure of centimeter dimension.

There are a number of forces acting on the CNT bundles which cause

them to stay together. It has been suggested that the sock forms due to ther-

mophoresis or inertial migration, and the CNT may accumulate at a certain

distance away from the wall [25]. The thermophoretic force is a result of

(A) (B) (C)

1 inch 1 µm 40 nm

Fig. 3.7 Hierarchical structure of CNT assembly: (A) cm-scale sock; (B) μm-scale network;

and (C) nm-scale bundles. (Reproduced with permission from Hou G, Ng V, Xu C, Zhang L,

Zhang G, Shanov V, et al. Multiscale modeling of carbon nanotube bundle agglomeration

inside a gas phase pyrolysis reactor. MRS Adv. (2017) 1–6.)