Page 55 - Carbon Nanotube Fibres and Yarns

P. 55

48 Carbon Nanotube Fibers and Yarns

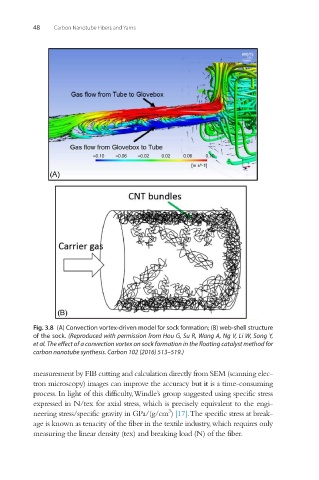

Fig. 3.8 (A) Convection vortex-driven model for sock formation; (B) web-shell structure

of the sock. (Reproduced with permission from Hou G, Su R, Wang A, Ng V, Li W, Song Y,

et al. The effect of a convection vortex on sock formation in the floating catalyst method for

carbon nanotube synthesis. Carbon 102 (2016) 513–519.)

measurement by FIB cutting and calculation directly from SEM (scanning elec-

tron microscopy) images can improve the accuracy but it is a time-consuming

process. In light of this difficulty, Windle’s group suggested using specific stress

expressed in N/tex for axial stress, which is precisely equivalent to the engi-

3

neering stress/specific gravity in GPa/(g/cm ) [17]. The specific stress at break-

age is known as tenacity of the fiber in the textile industry, which requires only

measuring the linear density (tex) and breaking load (N) of the fiber.