Page 237 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 237

200 Carraher’s Polymer Chemistry

6.4 POLYMERIZATION TECHNIQUES

The principle free radical polymerization techniques are bulk, solution, suspension, and emulsion.

Tables 6.5 and 6.6 briefly describe these techniques.

Bulk Polymerization: Bulk polymerization of a liquid monomer such as methyl methacrylate is rela-

tively simple in the absence of oxygen where small bottles or test tubes can be used as the reaction

vessel. The monomer can be heated in the presence of an initiator giving a clear plastic shaped like

the container, but a little smaller because of shrinkage. The volume of the monomers is generally

larger than the final polymers, thus, the density of the polymer is greater than that of the original

monomer.

The rate of bulk polymerization can be followed by monitoring the change in volume or

increase in viscosity. When the viscosity is high, the termination reaction is hindered since the

macroradicals are unable to diffuse readily in the viscous medium. Thus, the number of growing

chains increases. This autoacceleration, called the Norris–Trommsdorff, Tranmsdorff, or gel

effect, causes the formation of unusually high molecular weight chains. Since vinyl polymeriza-

tions are exothermic, there is a buildup of heat which further causes an additional autoaccelera-

tion of the reaction. If the temperature buildup is not controlled, it is possible that an explosion

will occur. While the temperature can be easily controlled within a small test tube, it is more

difficult in a large batch process. Stirring and external cooling are employed to control the poly-

merization process.

Suspension Polymerization: Water-insoluble monomers such as vinyl chloride may be polymerized

as suspended droplets (10–1000 nm in diameter) in a process called suspension (pearl) polymeriza-

tion. Coalescence of droplets is prevented by the use of small amounts of water-soluble polymers,

such as PVA. The suspension process is characterized by good heat control and ease of removal of

the discrete polymer particles.

Since PVC is insoluble in its monomer, it precipitates as formed in the droplet. This is actually

advantageous since it permits ready removal of any residual carcinogenic monomer from the solid

beads by stripping under reduced pressure.

Solution Polymerization: Monomers may also be polymerized in solution using good or poor sol-

vents for homogeneous and heterogeneous systems, respectively. In solution polymerizations, sol-

vents with low-chain transfer constants are used to minimize reduction in chain length.

Poly(vinyl acetate) (PVAc) may be produced by the polymerization of vinyl acetate (Equation 6.47).

The viscosity of the solution continues to increase until the reaction is complete. Dilute polymer

solutions are used to prevent the onset of autoacceleration because of the gel effect.

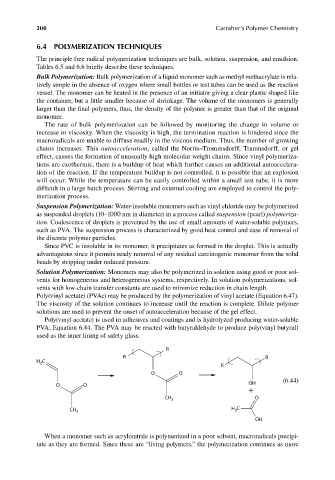

Poly(vinyl acetate) is used in adhesives and coatings and is hydrolyzed producing water-soluble

PVA; Equation 6.44. The PVA may be reacted with butyraldehyde to produce poly(vinyl butyral)

used as the inner lining of safety glass.

R

R R

H C

2

R

O O

(6.44)

O O OH

+

CH 3 O

CH 3 H C

3

OH

When a monomer such as acrylonitrile is polymerized in a poor solvent, macroradicals precipi-

tate as they are formed. Since these are “living polymers,” the polymerization continues as more

9/14/2010 3:39:36 PM

K10478.indb 200

K10478.indb 200 9/14/2010 3:39:36 PM