Page 390 - Centrifugal Pumps 2E

P. 390

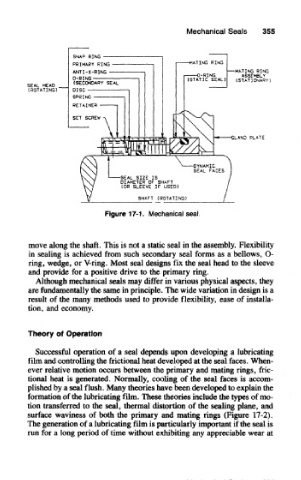

Mechanical Seals 355

Figure 17-1. Mechanical seal,

move along the shaft. This is not a static seal in the assembly. Flexibility

in sealing is achieved from such secondary seal forms as a bellows, O-

ring, wedge, or V-ring. Most seal designs fix the seal head to the sleeve

and provide for a positive drive to the primary ring.

Although mechanical seals may differ in various physical aspects, they

are fundamentally the same in principle. The wide variation in design is a

result of the many methods used to provide flexibility, ease of installa-

tion, and economy.

Theory of Operation

Successful operation of a seal depends upon developing a lubricating

film and controlling the ffictional heat developed at the seal faces. When-

ever relative motion occurs between the primary and mating rings, trie-

tional heat is generated. Normally, cooling of the seal faces is accom-

plished by a seal flush. Many theories have been developed to explain the

formation of the lubricating film. These theories include the types of mo-

tion transferred to the seal, thermal distortion of the sealing plane, and

surface waviness of both the primary and mating rings (Figure 17-2).

The generation of a lubricating film is particularly important if the seal is

run for a long period of time without exhibiting any appreciable wear at