Page 391 - Centrifugal Pumps 2E

P. 391

356 Centrifugal Pumps: Design and Application

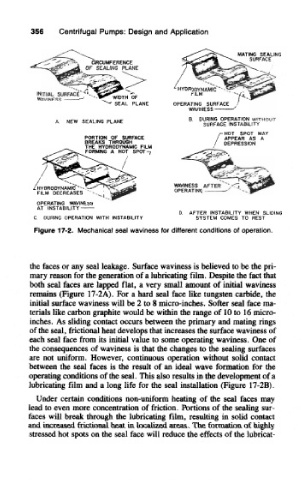

Figure 17-2. Mechanical seal waviness for different conditions of operation,

the faces or any seal leakage. Surface waviness is believed to be the pri-

mary reason for the generation of a lubricating film. Despite the fact that

both seal faces are lapped flat, a very small amount of initial waviness

remains (Figure 17-2A). For a hard seal face like tungsten carbide, the

initial surface waviness will be 2 to 8 micro-inches. Softer seal face ma-

terials like carbon graphite would be within the range of 10 to 16 micro-

inches. As sliding contact occurs between the primary and mating rings

of the seal, frictional heat develops that increases the surface waviness of

each seal face from its initial value to some operating waviness. One of

the consequences of waviness is that the changes to the sealing surfaces

are not uniform. However, continuous operation without solid contact

between the seal faces is the result of an ideal wave formation for the

operating conditions of the seal. This also results in the development of a

lubricating film and a long life for the seal installation (Figure 17-2B).

Under certain conditions non-uniform heating of the seal faces may

lead to even more concentration of friction. Portions of the sealing sur-

faces will break through the lubricating film, resulting in solid contact

and increased frictional heat in localized areas. The formation of highly

stressed hot spots on the seal face will reduce the effects of the lubricat-