Page 393 - Centrifugal Pumps 2E

P. 393

358 Centrifugal Pumps: Design and Application

thermoelastic instability has been observed under both dry and liquid lu-

bricated conditions.

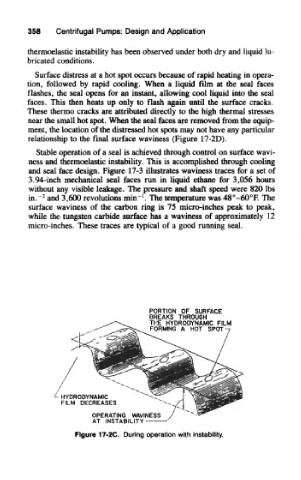

Surface distress at a hot spot occurs because of rapid heating in opera-

tion, followed by rapid cooling. When a liquid film at the seal faces

flashes, the seal opens for an instant, allowing cool liquid into the seal

faces. This then heats up only to flash again until the surface cracks.

These thermo cracks are attributed directly to the high thermal stresses

near the small hot spot. When the seal faces are removed from the equip-

ment, the location of the distressed hot spots may not have any particular

relationship to the final surface waviness (Figure 17-2D).

Stable operation of a seal is achieved through control on surface wavi-

ness and thermoelastic instability. This is accomplished through cooling

and seal face design. Figure 17-3 illustrates waviness traces for a set of

3.94-inch mechanical seal faces run in liquid ethane for 3,056 hours

without any visible leakage. The pressure and shaft speed were 820 Ibs

2 1

in.^ and 3,600 revolutions min" . The temperature was 48°~60°F. The

surface waviness of the carbon ring is 75 micro-inches peak to peak,

while the tungsten carbide surface has a waviness of approximately 12

micro-inches. These traces are typical of a good running seal.

Figure 17-2C. During operation with instability.