Page 392 - Centrifugal Pumps 2E

P. 392

Mechanical Seats 357

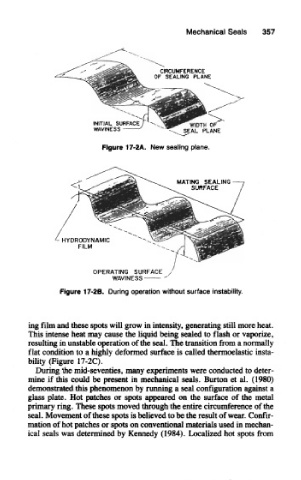

Figure 17-2B. During operation without surface instability.

ing film and these spots will grow in intensity, generating still more heat.

This intense heat may cause the liquid being sealed to flash or vaporize,

resulting in unstable operation of the seal. Hie transition from a normally

flat condition to a highly deformed surface is called thermoelastic insta-

bility (Figure 17-2C).

During the mid-seventies, many experiments were conducted to deter-

mine if mis could be present in mechanical seals. Burton et al. (1980)

demonstrated this phenomenon by running a seal configuration against a

glass plate. Hot patches or spots appeared on the surface of the metal

primary ring. These spots moved through the entire circumference of the

seal. Movement of these spots is believed to be the result of wear. Confir-

mation of hot patches or spots on conventional materials used in mechan-

ical seals was determined by Kennedy (1984). Localized hot spots from