Page 435 - Centrifugal Pumps 2E

P. 435

Mechanical Seals 399

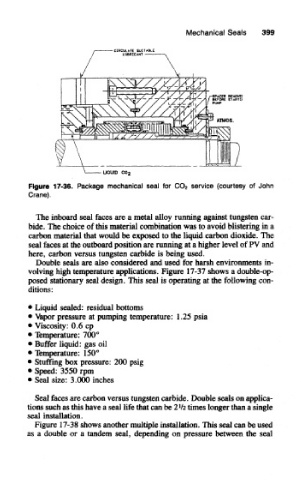

Figure 17-36. Package mechanical seal for CO 2 service (courtesy of John

Crane).

The inboard seal faces are a metal alloy running against tungsten car-

bide. The choice of this material combination was to avoid blistering in a

carbon material that would be exposed to the liquid carbon dioxide. The

seal faces at the outboard position are running at a higher level of PV and

here, carbon versus tungsten carbide is being used.

Double seals are also considered and used for harsh environments in-

volving high temperature applications. Figure 17-37 shows a double-op-

posed stationary seal design. This seal is operating at the following con-

ditions:

• Liquid sealed: residual bottoms

• Vapor pressure at pumping temperature: 1.25 psia

• Viscosity: 0.6 cp

« Temperature: 700°

• Buffer liquid: gas oil

• Temperature: 150°

• Stuffing box pressure: 200 psig

• Speed: 3550 rpm

« Seal size: 3.000 inches

Seal faces are carbon versus tungsten carbide. Double seals on applica-

tions such as this have a seal life that can be 2V2 times longer than a single

seal installation.

Figure 17-38 shows another multiple installation. This seal can be used

as a double or a tandem seal, depending on pressure between the seal