Page 431 - Centrifugal Pumps 2E

P. 431

Mechanical Seals 395

The measured leakage from each end of this horizontal pump was 10 to

120 ppm. This installation is a rotating seal head with a tungsten carbide

insert running on a silicon carbide mating ring. A steam quench is being

used on the atmospheric side of the seal.

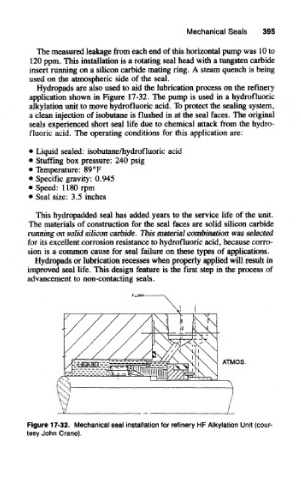

Hydropads are also used to aid the lubrication process on the refinery

application shown in Figure 17-32. The pump is used in a hydrofluoric

alkylation unit to move hydrofluoric acid. To protect the sealing system,

a clean injection of isobutane is flushed in at the seal faces. The original

seals experienced short seal life due to chemical attack from the hydro-

fluoric acid. The operating conditions for this application are:

• Liquid sealed: isobutane/hydrofluoric acid

» Stuffing box pressure: 240 psig

• Temperature: 89°F

• Specific gravity: 0,945

• Speed: llSOrpm

» Seal size: 3.5 inches

This hydropadded seal has added years to the service life of the unit,

The materials of construction for the seal faces are solid silicon carbide

running on solid silicon carbide. This material combination was selected

for its excellent corrosion resistance to hydrofluoric acid, because corro-

sion is a common cause for seal failure on these types of applications.

Hydropads or lubrication recesses when properly applied will result in

improved seal life. This design feature is the first step in the process of

advancement to non-contacting seals.

Figure 17-32. Mechanical seal installation for refinery HF Alkylation Unit (cour-

tesy John Crane).