Page 432 - Centrifugal Pumps 2E

P. 432

396 Centrifugal Pumps: Design and Application

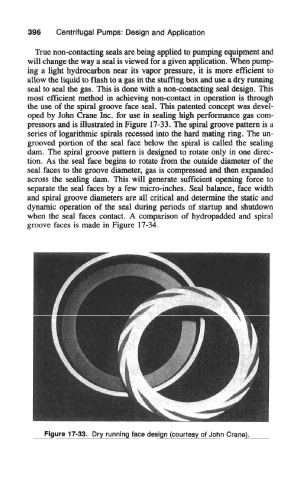

True non-contacting seals are being applied to pumping equipment and

will change the way a seal is viewed for a given application. When pump-

ing a light hydrocarbon near its vapor pressure, it is more efficient to

allow the liquid to flash to a gas in the stuffing box and use a dry running

seal to seal the gas. This is done with a non-contacting seal design. This

most efficient method in achieving non-contact in operation is through

the use of the spiral groove face seal. This patented concept was devel-

oped by John Crane Inc. for use in sealing high performance gas com-

pressors and is illustrated in Figure 17-33. The spiral groove pattern is a

series of logarithmic spirals recessed into the hard mating ring. The un-

grooved portion of the seal face below the spiral is called the sealing

dam. The spiral groove pattern is designed to rotate only in one direc-

tion. As the seal face begins to rotate from the outside diameter of the

seal faces to the groove diameter, gas is compressed and then expanded

across the sealing dam. This will generate sufficient opening force to

separate the seal faces by a few micro-inches. Seal balance, face width

and spiral groove diameters are all critical and determine the static and

dynamic operation of the seal during periods of startup and shutdown

when the seal faces contact. A comparison of hydropadded and spiral

groove faces is made in Figure 17-34,

Figure 17-33. Dry running face design (courtesy of John Crane).