Page 115 - Centrifugal Pumps Design and Application

P. 115

96 Centrifugal Pumps: Design and Application

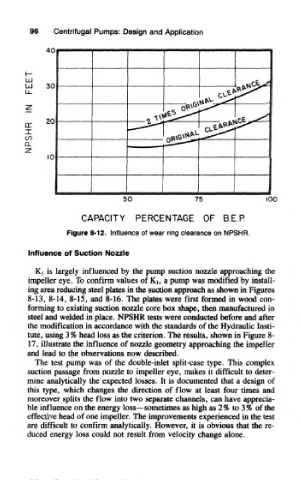

Figure 8-12. Influence of wear ring clearance on NPSHR.

Influence of Suction Nozzle

KI is largely influenced by the pump suction nozzle approaching the

impeller eye. To confirm values of KI, a pump was modified by install-

ing area reducing steel plates in the suction approach as shown in Figures

8-13, 8-14, 8-15, and 8-16. The plates were first formed in wood con-

forming to existing suction nozzle core box shape, then manufactured in

steel and welded in place. NPSHR tests were conducted before and after

the modification in accordance with the standards of the Hydraulic Insti-

tute, using 3% head loss as the criterion. The results, shown in Figure 8-

17, illustrate the influence of nozzle geometry approaching the impeller

and lead to the observations now described.

The test pump was of the double-inlet split-case type. This complex

suction passage from pozzle to impeller eye, makes it difficult to deter-

mine analytically the expected losses. It is documented that a design of

this type, which changes the direction of flow at least four times and

moreover splits the flow into two separate channels, can have apprecia-

ble influence on the energy loss—sometimes as high as 2% to 3% of the

effective head of one impeller. The improvements experienced in the test

are difficult to confirm analytically. However, it is obvious that the re-

duced energy loss could not result from velocity change alone.