Page 136 - Centrifugal Pumps Design and Application

P. 136

114 Centrifugal Pumps: Design and Application

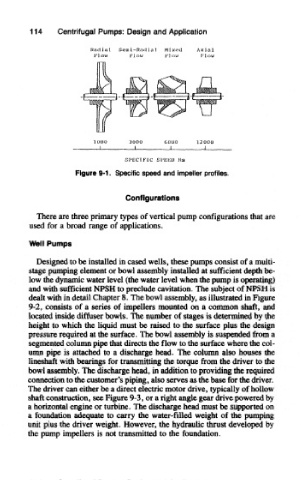

Figure 9-1. Specific speed and impeller profiles.

Configurations

There are three primary types of vertical pump configurations that are

used for a broad range of applications.

Well Pumps

Designed to be installed in cased wells, these pumps consist of a multi-

stage pumping element or bowl assembly installed at sufficient depth be-

low the dynamic water level (the water level when the pump is operating)

and with sufficient NPSH to preclude cavitation. The subject of NPSH is

dealt with in detail Chapter 8. The bowl assembly, as illustrated in Figure

9-2, consists of a series of impellers mounted on a common shaft, and

located inside diffuser bowls. The number of stages is determined by the

height to which the liquid must be raised to the surface plus the design

pressure required at the surface. The bowl assembly is suspended from a

segmented column pipe mat directs the flow to the surface where the col-

umn pipe is attached to a discharge head. The column also houses the

lineshaft with bearings for transmitting the torque from the driver to the

bowl assembly. The discharge head, in addition to providing the required

connection to the customer's piping, also serves as the base for the driver.

The driver can either be a direct electric motor drive, typically of hollow

shaft construction, see Figure 9-3, or a right angle gear drive powered by

a horizontal engine or turbine. The discharge head must be supported on

a foundation adequate to carry the water-filled weight of the pumping

unit plus the driver weight. However, the hydraulic thrust developed by

the pump impellers is not transmitted to the foundation.