Page 140 - Centrifugal Pumps Design and Application

P. 140

118 Centrifugal Pumps: Design and Application

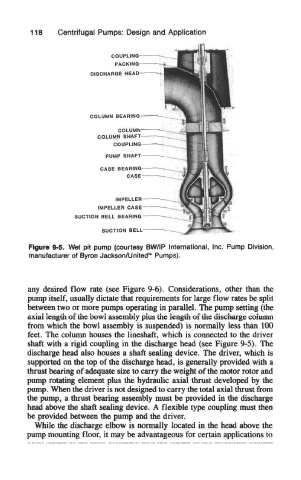

Figure 9*5. Wet pit pump (courtesy BW/IP international, inc. Pump Division,

manufacturer of Byron Jackson/United™ Pumps).

any desired flow rate (see Figure 9-6). Considerations, other than the

pump itself, usually dictate that requirements for large flow rates be split

between two or more pumps operating in parallel. The pump setting (the

axial length of the bowl assembly plus the length of the discharge column

from which the bowl assembly is suspended) is normally less than 100

feet. The column houses the lineshaft, which is connected to the driver

shaft with a rigid coupling in the discharge head (see Figure 9-5). The

discharge head also houses a shaft sealing device. The driver, which is

supported on the top of the discharge head, is generally provided with a

thrust bearing of adequate size to carry the weight of the motor rotor and

pump rotating element plus the hydraulic axial thrust developed by the

pump. When the driver is not designed to carry the total axial thrust from

the pump, a thrust bearing assembly must be provided in the discharge

head above the shaft sealing device. A flexible type coupling must then

be provided between the pump and the driver.

While the discharge elbow is normally located in the head above the

pump mounting floor, it may be advantageous for certain applications to