Page 138 - Centrifugal Pumps Design and Application

P. 138

116 Centrifugal Pumps: Design and Application

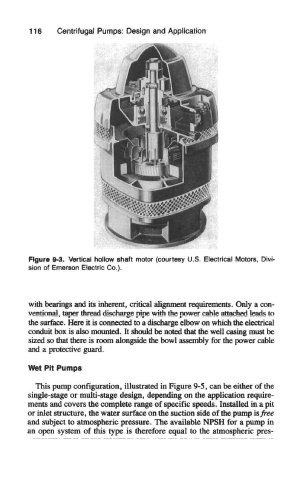

Figure 9-3. Vertical hollow shaft motor (courtesy U.S. Electrical Motors, Divi-

sion of Emerson Electric Co.).

with bearings and its inherent, critical alignment requirements. Only a con-

ventional, taper thread discharge pipe with the power cable attached leads to

the surface. Here it is connected to a discharge elbow on which the electrical

conduit box is also mounted. It should be noted that the well casing must be

sized so that there is room alongside the bowl assembly for the power cable

and a protective guard.

Wet Pit Pumps

This pump configuration, illustrated in Figure 9-5, can be either of the

single-stage or multi-stage design, depending on the application require-

merits and covers the complete range of specific speeds. Installed in a pit

or inlet structure, the water surface on the suction side of the pump is free

and subject to atmospheric pressure. The available NPSH for a pump in

an open system of this type is therefore equal to the atmospheric pres-