Page 135 - Chalcogenide Glasses for Infrared Optics

P. 135

112 Cha pte r F o u r

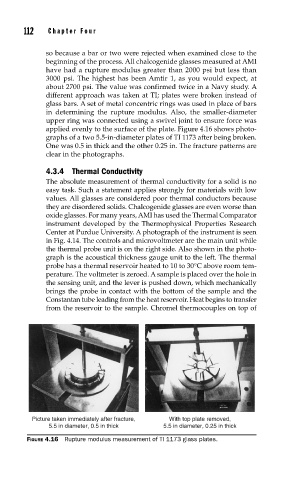

so because a bar or two were rejected when examined close to the

beginning of the process. All chalcogenide glasses measured at AMI

have had a rupture modulus greater than 2000 psi but less than

3000 psi. The highest has been Amtir 1, as you would expect, at

about 2700 psi. The value was confirmed twice in a Navy study. A

different approach was taken at TI; plates were broken instead of

glass bars. A set of metal concentric rings was used in place of bars

in determining the rupture modulus. Also, the smaller-diameter

upper ring was connected using a swivel joint to ensure force was

applied evenly to the surface of the plate. Figure 4.16 shows photo-

graphs of a two 5.5-in-diameter plates of TI 1173 after being broken.

One was 0.5 in thick and the other 0.25 in. The fracture patterns are

clear in the photographs.

4.3.4 Thermal Conductivity

The absolute measurement of thermal conductivity for a solid is no

easy task. Such a statement applies strongly for materials with low

values. All glasses are considered poor thermal conductors because

they are disordered solids. Chalcogenide glasses are even worse than

oxide glasses. For many years, AMI has used the Thermal Comparator

instrument developed by the Thermophysical Properties Research

Center at Purdue University. A photograph of the instrument is seen

in Fig. 4.14. The controls and microvoltmeter are the main unit while

the thermal probe unit is on the right side. Also shown in the photo-

graph is the acoustical thickness gauge unit to the left. The thermal

probe has a thermal reservoir heated to 10 to 30°C above room tem-

perature. The voltmeter is zeroed. A sample is placed over the hole in

the sensing unit, and the lever is pushed down, which mechanically

brings the probe in contact with the bottom of the sample and the

Constantan tube leading from the heat reservoir. Heat begins to transfer

from the reservoir to the sample. Chromel thermocouples on top of

Picture taken immediately after fracture, With top plate removed,

5.5 in diameter, 0.5 in thick 5.5 in diameter, 0.25 in thick

FIGURE 4.16 Rupture modulus measurement of TI 1173 glass plates.