Page 138 - Chalcogenide Glasses for Infrared Optics

P. 138

Characterization of Glass Pr operties 115

balance. Sealed in the quartz containers, the finished composition is

guaranteed. Each step of the compounding casting process is con-

trolled by a computer program. A unique program in temperature

and time is developed and stored for each glass composition pro-

duced. Generally, the process, start to finish, takes 48 h.

After the process ends, the quartz container is broken and the

plate is removed. Preliminary evaluation consists of an FTIR scan and

examination for particles, bubbles, and fractures using an infrared

microscope. If the plate is judged good, the anneal cycle is next. The

anneal furnace is large with a good circulation of air. The plate is

heated up to an anneal point near the Tg and then held at this tem-

perature for several hours. Cooldown is slow, perhaps 1° per hour for

the first 20° then faster to room temperature. Anneal cycles vary for

each glass, lasting from 3 to 5 days. The thermal history of the glass

has an effect on the refractive index in the last three to four decimals.

The process should be fixed before the final refractive measurements

are made and the numbers distributed. Once established, the anneal

process should not be changed.

After anneal, the plate is ground flat and parallel and is polished;

transmission is measured and checked against standards and exam-

ined again for particles. Results are recorded on the QC sheet for the

plate. Each plate has a number assigned in the beginning, and the

sheet is kept on file for future reference.

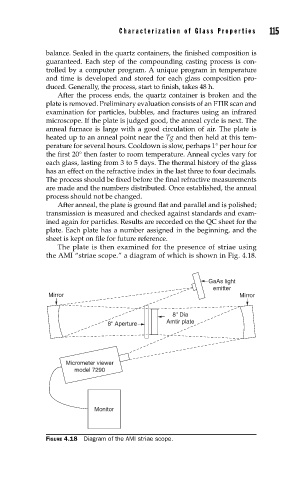

The plate is then examined for the presence of striae using

the AMI “striae scope.” a diagram of which is shown in Fig. 4.18.

GaAs light

emitter

Mirror Mirror

8" Dia

8" Aperture Amtir plate

Micrometer viewer

model 7290

Monitor

FIGURE 4.18 Diagram of the AMI striae scope.