Page 180 - Chalcogenide Glasses for Infrared Optics

P. 180

156 Cha pte r Se v e n

In 1982 prior to this program, AMI suddenly had a serious prob-

lem in producing Amtir 1 glass due to excess absorption. We found

out our KBI source selenium was really produced by Asarco in Amarillo.

A visit there revealed that they had shut down their high-purity unit

2 years earlier. Asarco had selected a certain fraction of selenium in

the distillation process they had learned produced excellent results

for our application. Asarco continued supplying AMI out of their

inventory. When that fraction was exhausted, the material supplied

to us contained too much iron which lowered the overall transmis-

sion of the glass. We switched to the Belgium source marketed in the

United States by Indussa.

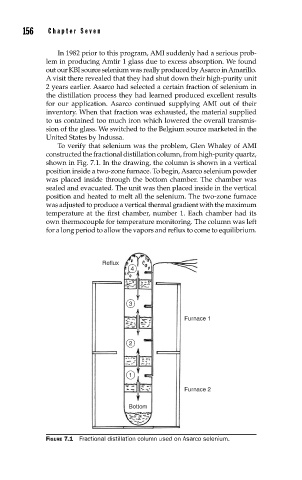

To verify that selenium was the problem, Glen Whaley of AMI

constructed the fractional distillation column, from high-purity quartz,

shown in Fig. 7.1. In the drawing, the column is shown in a vertical

position inside a two-zone furnace. To begin, Asarco selenium powder

was placed inside through the bottom chamber. The chamber was

sealed and evacuated. The unit was then placed inside in the vertical

position and heated to melt all the selenium. The two-zone furnace

was adjusted to produce a vertical thermal gradient with the maximum

temperature at the first chamber, number 1. Each chamber had its

own thermocouple for temperature monitoring. The column was left

for a long period to allow the vapors and reflux to come to equilibrium.

Reflux

4

3

Furnace 1

2

1

Furnace 2

Bottom

FIGURE 7.1 Fractional distillation column used on Asarco selenium.