Page 184 - Chalcogenide Glasses for Infrared Optics

P. 184

160 Cha pte r Se v e n

Pressure

gauge Forming gas

Furnace Stainless steel

pressure chamber

Glass cylinder

Thermocouple

and Laser

temperature

micrometer

controller

90.25

Heated, split-die

cladding glass

Heated, split-die

plastic coating

Spooler

Traverse

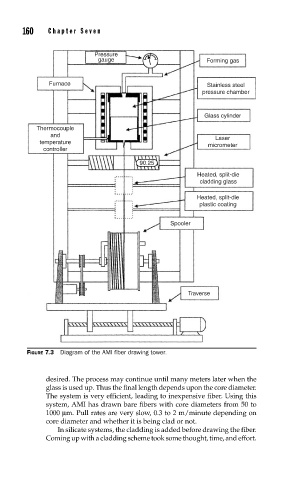

FIGURE 7.3 Diagram of the AMI fi ber drawing tower.

desired. The process may continue until many meters later when the

glass is used up. Thus the final length depends upon the core diameter.

The system is very efficient, leading to inexpensive fiber. Using this

system, AMI has drawn bare fibers with core diameters from 50 to

1000 µm. Pull rates are very slow, 0.3 to 2 m/minute depending on

core diameter and whether it is being clad or not.

In silicate systems, the cladding is added before drawing the fiber.

Coming up with a cladding scheme took some thought, time, and effort.