Page 206 - Chalcogenide Glasses for Infrared Optics

P. 206

182 Cha pte r Ei g h t

we had already learned, it is very difficult to make chalcogenide glass

rods that are homogeneous. The ribbon stacking method is well

suited for the chalcogenide glass fibers, particularly considering the

AMI method of drawing fibers.

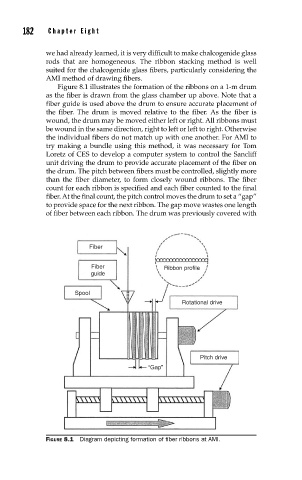

Figure 8.1 illustrates the formation of the ribbons on a 1-m drum

as the fiber is drawn from the glass chamber up above. Note that a

fiber guide is used above the drum to ensure accurate placement of

the fiber. The drum is moved relative to the fiber. As the fiber is

wound, the drum may be moved either left or right. All ribbons must

be wound in the same direction, right to left or left to right. Otherwise

the individual fibers do not match up with one another. For AMI to

try making a bundle using this method, it was necessary for Tom

Loretz of CES to develop a computer system to control the Sancliff

unit driving the drum to provide accurate placement of the fiber on

the drum. The pitch between fibers must be controlled, slightly more

than the fiber diameter, to form closely wound ribbons. The fiber

count for each ribbon is specified and each fiber counted to the final

fiber. At the final count, the pitch control moves the drum to set a “gap”

to provide space for the next ribbon. The gap move wastes one length

of fiber between each ribbon. The drum was previously covered with

Fiber

Fiber Ribbon profile

guide

Spool

Rotational drive

Pitch drive

“Gap”

FIGURE 8.1 Diagram depicting formation of fi ber ribbons at AMI.