Page 212 - Chalcogenide Glasses for Infrared Optics

P. 212

188 Cha pte r Ei g h t

qualitative, showing the shape of the transmission curve. We found

that most all the 8- to 12-µm energy was missing. The thinned epoxy

used to cement the ribbons was 1 to 2 in long. The epoxy also served

as cladding at each end of the bundle. However, at the end where the

light entered the bundle at oblique angles, it underwent many reflec-

tions against the epoxy surface that absorbed most all the 8- to 12-µm

energy. At this point, AMI had two infrared cameras to use for evalu-

ation of the imaging bundles. The Agema 210 3- to 5-µm camera had

a linear PbSe detector array, was thermoelectric cooled, and was

made by Magnavox. It was not very expensive or very sensitive. The

second camera was Raytheon Palm IR sensitive in the 8- to 12-µm

range, which used an uncooled barium-strontium-titanate (BST)

detector array. In both cases, the bundles were imaged directly to the

camera optics using 2-in-diameter meniscus lenses fabricated from

Amtir 1 glass. One was antireflection-coated for 3 to 5 µm for the

Agema camera and the other for 8 to 12 µm for the Palm IR camera.

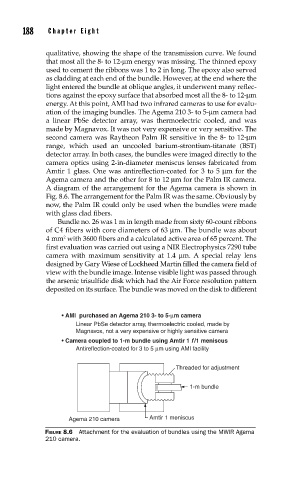

A diagram of the arrangement for the Agema camera is shown in

Fig. 8.6. The arrangement for the Palm IR was the same. Obviously by

now, the Palm IR could only be used when the bundles were made

with glass clad fibers.

Bundle no. 26 was 1 m in length made from sixty 60-count ribbons

of C4 fibers with core diameters of 63 µm. The bundle was about

4 mm with 3600 fibers and a calculated active area of 65 percent. The

2

first evaluation was carried out using a NIR Electrophysics 7290 tube

camera with maximum sensitivity at 1.4 µm. A special relay lens

designed by Gary Wiese of Lockheed Martin filled the camera field of

view with the bundle image. Intense visible light was passed through

the arsenic trisulfide disk which had the Air Force resolution pattern

deposited on its surface. The bundle was moved on the disk to different

• AMI purchased an Agema 210 3- to 5-µm camera

Linear PbSe detector array, thermoelectric cooled, made by

Magnavox, not a very expensive or highly sensitive camera

• Camera coupled to 1-m bundle using Amtir 1 f /1 meniscus

Antireflection-coated for 3 to 5 µm using AMI facility

Threaded for adjustment

1-m bundle

Agema 210 camera Amtir 1 meniscus

FIGURE 8.6 Attachment for the evaluation of bundles using the MWIR Agema

210 camera.