Page 174 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 174

152 CORROSION CAUSES

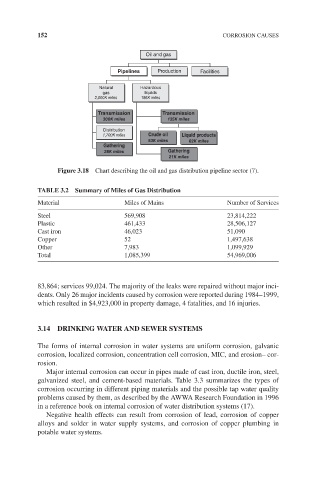

Oil and gas

Pipelines Production Facilities

Natural Hazardous

gas liquids

2,000K miles 156K miles

Transmission Transmission

300K miles 135K miles

Distribution

1,700K miles Crude oil Liquid products

53K miles 82K miles

Gathering

28K miles Gathering

21K miles

Figure 3.18 Chart describing the oil and gas distribution pipeline sector (7).

TABLE 3.2 Summary of Miles of Gas Distribution

Material Miles of Mains Number of Services

Steel 569,908 23,814,222

Plastic 461,433 28,506,127

Cast iron 46,023 51,090

Copper 52 1,497,638

Other 7,983 1,099,929

Total 1,085,399 54,969,006

83,864; services 99,024. The majority of the leaks were repaired without major inci-

dents. Only 26 major incidents caused by corrosion were reported during 1984–1999,

which resulted in $4,923,000 in property damage, 4 fatalities, and 16 injuries.

3.14 DRINKING WATER AND SEWER SYSTEMS

The forms of internal corrosion in water systems are uniform corrosion, galvanic

corrosion, localized corrosion, concentration cell corrosion, MIC, and erosion– cor-

rosion.

Major internal corrosion can occur in pipes made of cast iron, ductile iron, steel,

galvanized steel, and cement-based materials. Table 3.3 summarizes the types of

corrosion occurring in different piping materials and the possible tap water quality

problems caused by them, as described by the AWWA Research Foundation in 1996

in a reference book on internal corrosion of water distribution systems (17).

Negative health effects can result from corrosion of lead, corrosion of copper

alloys and solder in water supply systems, and corrosion of copper plumbing in

potable water systems.