Page 367 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 367

CORROSION DAMAGE, DEFECTS, AND FAILURES 345

DOM.

CW LINE

HW sto. tank–1 HW sto. tank–2

C.V. C.V.

HW recirc.

pump

LP steam LP steam

Heat HW recirc. Heat

exchanger–1 line exchanger–2

Cond. F&T TRAP

Condensate

tank

Condensate

pumps

Pumped

condensate

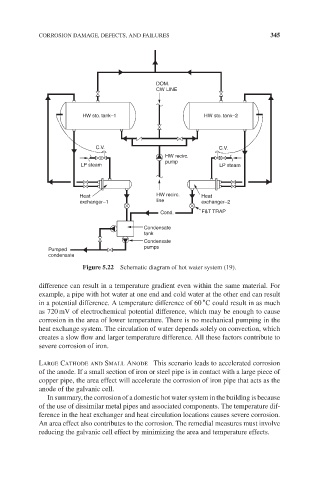

Figure 5.22 Schematic diagram of hot water system (19).

difference can result in a temperature gradient even within the same material. For

example, a pipe with hot water at one end and cold water at the other end can result

∘

in a potential difference. A temperature difference of 60 C could result in as much

as 720 mV of electrochemical potential difference, which may be enough to cause

corrosion in the area of lower temperature. There is no mechanical pumping in the

heat exchange system. The circulation of water depends solely on convection, which

creates a slow flow and larger temperature difference. All these factors contribute to

severe corrosion of iron.

Large Cathode and Small Anode This scenario leads to accelerated corrosion

of the anode. If a small section of iron or steel pipe is in contact with a large piece of

copper pipe, the area effect will accelerate the corrosion of iron pipe that acts as the

anode of the galvanic cell.

In summary, the corrosion of a domestic hot water system in the building is because

of the use of dissimilar metal pipes and associated components. The temperature dif-

ference in the heat exchanger and heat circulation locations causes severe corrosion.

An area effect also contributes to the corrosion. The remedial measures must involve

reducing the galvanic cell effect by minimizing the area and temperature effects.