Page 368 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 368

346 CONSEQUENCES OF CORROSION

The high amounts of Al and Zn reported may be because of the use of galvanized

pipes and a sacrificial anode cathodic protection system in the hot water tank.

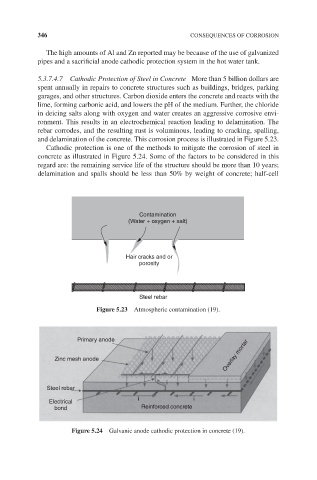

5.3.7.4.7 Cathodic Protection of Steel in Concrete More than 5 billion dollars are

spent annually in repairs to concrete structures such as buildings, bridges, parking

garages, and other structures. Carbon dioxide enters the concrete and reacts with the

lime, forming carbonic acid, and lowers the pH of the medium. Further, the chloride

in deicing salts along with oxygen and water creates an aggressive corrosive envi-

ronment. This results in an electrochemical reaction leading to delamination. The

rebar corrodes, and the resulting rust is voluminous, leading to cracking, spalling,

and delamination of the concrete. This corrosion process is illustrated in Figure 5.23.

Cathodic protection is one of the methods to mitigate the corrosion of steel in

concrete as illustrated in Figure 5.24. Some of the factors to be considered in this

regard are: the remaining service life of the structure should be more than 10 years;

delamination and spalls should be less than 50% by weight of concrete; half-cell

Contamination

(Water + oxygen + salt)

Hair cracks and or

porosity

Steel rebar

Figure 5.23 Atmospheric contamination (19).

Primary anode

Overlay mortar

Zinc mesh anode

i

Steel rebar

i i

Electrical

bond Reinforced concrete

Figure 5.24 Galvanic anode cathodic protection in concrete (19).