Page 158 - Chemical Process Equipment - Selection and Design

P. 158

130 FLUID TRANSPORT EQUIPMENT

percentage type is preferred. In fact, a majority of characterized These characteristics and other properties of 15 kinds of valves

valves currently are equal percentage. are described by Chalfin (1980).

Rangeability is the ratio of maximum to minimum flows over Pressure drop. Good control requires a substantial pressure

which the valve can give good control. This concept is difficult to drop through the valve. For pumped systems, the drop through the

quantify and is not used much for valve selection. A valve generally valve should be at least 1/3 of the pressure drop in the system, with

can be designed properly for a suitably wide flow range. a minimum of 15 psi. When the expected variation in flow is small,

Recovery is a measure of the degree of pressure recovery at the this rule can be relaxed. In long liquid transportation lines, for

valve outlet from the low pressure at the vena contracta. When instance, a fully open control valve may absorb less than 1% of the

flashing occurs at the vena contracta and the pressure recovery is system pressure drop. In systems with centrifugal pumps, the

high, the bubbles collapse with resulting cavitation and noise. The variation of head with capacity must be taken into account when

more streamlined the valve, the more complete the pressure sizing the valve. Example 7.2, for instance, illustrates how the valve

recovery; thus, from this point of view streamlining seems to be an drop may vary with flow in such a system.

undesirable quality. A table of recovery factors of a number of Types of valves. Most flow control valves are operated with

valve types is given by Chalfin (1980); such data usually are adjustable air pressure on a diaphragm, as in Figure 7.l(d), since

provided by manufacturers. this arrangement is more rapid, more sensitive and cheaper than

Hondwbeel

I Or

-Packing

\Bonnet

(a)

I 1

(e)

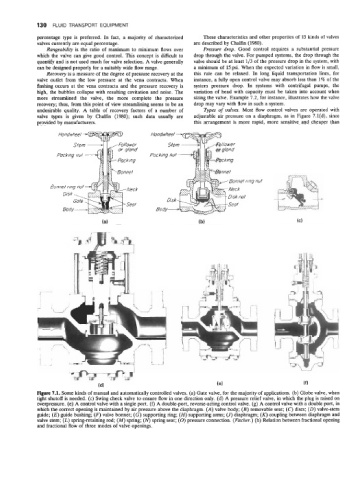

Figure 7.1. Some kinds of manual and automatically controlled valves. (a) Gate valve, for the majority of applications. (b) Globe valve, when

tight shutoff is needed. (c) Swing check valve to ensure flow in one direction only. (d) A pressure relief valve, in which the plug is raised on

overpressure. (e) A control valve with a single port. (f) A double-port, reverse-acting control valve. (g) A control valve with a double port, in

which the correct opening is maintained by air pressure above the diaphragm. (A) valve body; (B) removable seat; (C) discs; (D) valve-stem

guide; (E) guide bushing; (F) valve bonnet; (G) supporting ring; (H) supporting arms; (J) diaphragm; (K) coupling between diaphragm and

valve stem; (L) spring-retaining rod; (M) spring; (N) spring seat; (0) pressure connection. (Fischer.) (h) Relation between fractional opening

and fractional flow of three modes of valve openings.