Page 27 - Chemical Process Equipment - Selection and Design

P. 27

4 INTRODUCTION

of the entity that occurs without a crossing of the boundary; for

example, an increase in the sensible enthalpy or in the amount of a

substance as a consequence of chemical reaction. Analogously,

sinks are decreases without a boundary crossing, as the dis-

appearance of water from a fluid stream by adsorption onto a solid

phase within the boundary.

Accumulations are time rates of change of the amount of the

entities within the boundary. For example, in the absence of sources

and sinks, an accumulation occurs when the input and output rates

are different. In the steady state, the accumulation is zero.

Although the principle of balancing is simple, its application

requires knowledge of the performance of all the kinds of

equipment comprising the system and of the phase relations and

physical properties of all mixtures that participate in the process. As

a consequence of trying to cover a variety of equipment and

processes, the books devoted to the subject of material and energy

balances always run to several hundred pages. Throughout this D

book, material and energy balances are utilized in connection with

the design of individual kinds of equipment and some processes. 20

Cases involving individual pieces of equipment usually are relatively 20

easy to balance, for example, the overall balance of a distillation

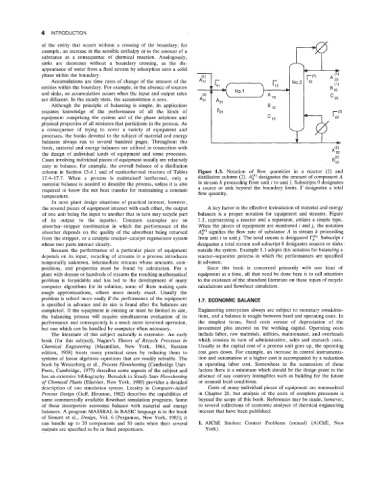

column in Section 13.4.1 and of nonisothermal reactors of Tables Figure 1.3. Notation of flow quantities in a reactor (1) and

17.4-17.7. When a process is maintained isothermal, only a distillation column (2). AF) designates the amount of component A

material balance is needed to describe the process, unless it is also in stream k proceeding from unit i to unit j. Subscripts 0 designates

required to know the net heat transfer for maintaining a constant a source or sink beyond the boundary limits. r designates a total

temperature. flow quantity.

In most plant design situations of practical interest, however,

the several pieces of equipment interact with each other, the output A key factor in the effective formulation of material and energy

of one unit being the input to another that in turn may recycle part balances is a proper notation for equipment and streams. Figure

of its output to the inputter. Common examples are an 1.3, representing a reactor and a separator, utilizes a simple type.

absorber-stripper combination in which the performance of the When the pieces of equipment are numbered i and j, the notation

absorber depends on the quality of the absorbent being returned AF) signifies the flow rate of substance A in stream k proceeding

from the stripper, or a catalytic cracker-catalyst regenerator system from unit i to unit j. The total stream is designated I?F). Subscript t

whose two parts interact closely. designates a total stream and subscript 0 designates sources or sinks

Because the performance of a particular piece of equipment outside the system. Example 1.1 adopts this notation for balancing a

depends on its input, recycling of streams in a process introduces reactor-separator process in which the performances are specified

temporarily unknown, intermediate streams whose amounts, com- in advance.

positions, and properties must be found by calculation. For a Since this book is concerned primarily with one kind of

plant with dozens or hundreds of streams the resulting mathematical equipment at a time, all that need be done here is to call attention

problem is formidable and has led to the development of many to the existence of the abundant literature on these topics of recycle

computer algorithms for its solution, some of them making quite calculations and flowsheet simulation.

rough approximations, others more nearly exact. Usually the

problem is solved more easily if the performance of the equipment 1.7. ECONOMIC BALANCE

is specified in advance and its size is found after the balances are

completed. If the equipment is existing or must be limited in size, Engineering enterprises always are subject to monetary considera-

the balancing process will require simultaneous evaluation of its tions, and a balance is sought between fixed and operating costs. In

performance and consequently is a much more involved operation, the simplest terms, fixed costs consist of depreciation of the

but one which can be handled by computer when necessary. investment plus interest on the working capital. Operating costs

The literature of this subject naturally is extensive. An early include labor, raw materials, utilities, maintenance, and overheads

book (for this subject), Nagiev’s Theory of Recycle Processes in which consists in turn of administrative, sales and research costs.

Chemical Engineering (Macmillan, New York, 1964, Russian Usually as the capital cost of a process unit goes up, the operating

edition, 1958) treats many practical cases by reducing them to cost goes down. For example, an increase in control instrumenta-

systems of linear algebraic equations that are readily solvable. The tion and automation at a higher cost is accompanied by a reduction

book by Westerberg et al., Process Flowsheeting (Cambridge Univ. in operating labor cost. Somewhere in the summation of these

Press, Cambridge, 1977) describes some aspects of the subject and factors there is a minimum which should be the design point in the

has an extensive bibliography. Benedek in Steady State Flowsheeting absence of any contrary intangibles such as building for the future

of Chemical Plants (Elsevier, New York, 1980) provides a detailed or unusual local conditions.

description of one simulation system. Leesley in Computer-Aided Costs of many individual pieces of equipment are summarized

Process Design (Gulf, Houston, 1982) describes the capabilities of in Chapter 20, but analysis of the costs of complete processes is

some commercially available flowsheet simulation programs. Some beyond the scope of this book. References may be made, however,

of these incorporate economic balance with material and energy to several collections of economic analyses of chemical engineering

balances. A program MASSBAL in BASIC language is in the book interest that have been published:

of Sinnott et al., Design, Vol. 6 (Pergamon, New York, 1983); it

can handle up to 20 components and 50 units when their several 1. AIChE Student Contest Problems (annual) (AIChE, New

outputs are specified to be in fixed proportions. York) .