Page 28 - Chemical Process Equipment - Selection and Design

P. 28

1.7. ECONOMIC BALANCE 5

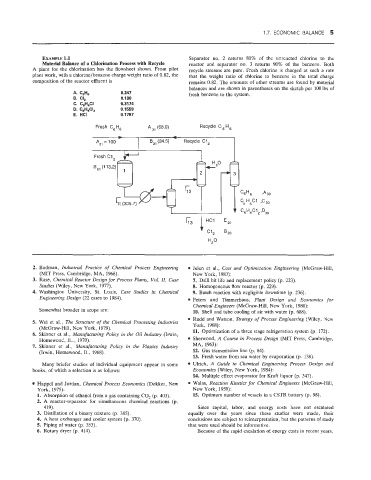

EXAMPLE Separator no. 2 returns 80% of the unreacted chlorine to the

1.1

Material Balance of a Chlorination Process with Recycle reactor and separator no. 3 returns 90% of the benzene. Both

A plant for the chlorination has the fiowsheet shown. From pilot recycle streams are pure. Fresh chlorine is charged at such a rate

plant work, with a chlorine/benzene charge weight ratio of 0.82, the that the weight ratio of chlorine to benzene in the total charge

composition of the reactor effluent is remains 0.82. The amounts of other streams are found by material

balances and are shown in parentheses on the sketch per 100 lbs of

A. C,H, 0.247 fresh benzene to the system.

. GI, 0.100

c. G,H,CI 0.3174

D. C,,H,C12 0.1559

E. HGI ID. 1797

Recycle C H ,

-

r

A,, = 100 B2, (24.5) Recycle C1,

Fresh C1 ,

Bo, (1 13.2)

vA30

c, H5C1 $30

‘6 H4C12 ’D3~

2. Bodman, Industrial Practice of Chemical Process Engineering @ Jelen et al., Cost and Optimization Engineering (McGraw-Hill,

(MIT Press, Cambridge, MA, 1968). New York, 1983):

3. Rase, Chemical Reactor Design for Process Plants, Vol. KI, Case 7. Drill bit life and replacement policy (p. 223).

Studies (Wiley, New York, 1977). 8. Homogeneous flow reactor (p. 229).

4. Washington University, St. Louis, Case Studies in Chemical 9. Batch reaction with negligible downtime (p. 236).

Engineering Design (22 cases to 1984). @ Peters and Timmerhaus, Plant Design and Economics for

Chemical Engineers (McGraw-Hill, New York, 1980):

Somewhat broader in scope are: 10. Shell and tube cooling of air with water (p. 688).

0 Rudd and Watson, Strategy of Process Engineering (Wiley, Vew

5. Wei et al., The Structure of the Chemical Processing Industries

(McGraw-Hill, New York, 1979). York, 1968):

6. Skinner et al., Manufacturing Policy in the Oil Industry (Irwin, 11. Optimization of a three stage refrigeration system (p. 172).

Homewood, IL., 1970). 0 Sherwood, A Course in Process Design (MIT Press, Cambridge,

7. Skinner e6 al., Manufacturing Policy in the Plastics Industry MA, 1963):

(Irwin, Homewood, II., 1968). 12. Gas transmission line (p. 84).

13. Fresh water from sea water by evaporation (p. 138).

Many briefer studies of individual equipment appear in some @ Ulrich, A Guide to Chemical Engineering Process Design and

books, of which a selection is as follows: Economics (Wiley, New York, 1984):

14. Multiple effect evaporator for Kraft liquor (p. 347).

Happel and Jordan, Chemical Process Economics (Dekker, New @ Walas, Reaction Kinetics for Chemical Engineers (McGraw-Hill,

York, 1975): New York, 1959):

1. Absorption of ethanol from a gas containing CO, (p. 403). 15. Optimum number of vessels in a CSTR battery (p. 98).

2. A reactor-separator for simultaneous chemical reactions (p.

419). Since capital, labor, and energy costs have not escalated

3. Distillation of a binary mixture (p. 385). equally over the years since these studies were made, their

4. A heat exchanger and cooler system (p. 370). conclusions are subject to reinterpretation, but the patterns of study

5. Piping of water (p. 353). that were used should be informative.

6. Rotary dryer (p. 414). Because of the rapid escalation of energy costs in recent years,