Page 33 - Chemical Process Equipment - Selection and Design

P. 33

10 INTRODUCTION

EXAMPLE l.%(continued)

Superheater Rows in line and spaced on 3-in. centers

12 rows of 21411. OD tubes (0.165-in. thick), 47 tubes per row spaced on 3-in. centers

17.44 ft long S = 2460 sqft

Rows in line and spaced on 3t-in. centers A, = 42 sqft

23 tubes per row spaced on 6-in. centers Air heater

S = 3150 sqft 53 rows of 2-in. OD tubes (0.083-in. thick),

A, = 133 sqft approx 13 ft long

Boiler Rows in line and spaced on 2i-in. centers

25 rows of 244x1. OD tubes, approx 18 ft long 41 tubes per row spaced on 3i-in. centers

Rows in line and spaced on 3a-in. centers S = 14,800 sqft

35 tubes per row spaced on 4-in. centers A, (total internal cross section area of 2173 tubes)

S = 10,300 sqft = 39.3 sqft

A, = 85.0 sqft A, (clear area between tubes for crossflow of air)

Economizer = 70 sqft

10 rows of 2-in. OD tubes (0.148-in. thick), Air temperature entering air heater = 80°F

approx 10 ft long

Steam out

(a) Gas Steam Coil

('' Outlet Air Heater

Coa I

fl

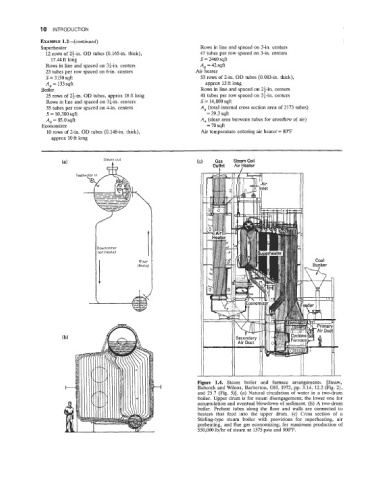

Figure 1.4. Steam boiler and furnace arrangements. [Steam,

Babcock and Wilcox, Barberton, OH, 1972, pp. 3.14, 12.2 (Fig. 2),

and 25.7 (Fig. 5)]. (a) Natural circulation of water in a two-drum

boiler. Upper drum is for steam disengagement; the lower one for

accumulation and eventual blowdown of sediment. (b) A two-drum

boiler. Preheat tubes along the floor and walls are connected to

heaters that feed into the upper drum. (c) Cross section of a

Stirling-type steam boiler with provisions for superheating, air

preheating, and flue gas economizing; for maximum production of

550,000 lb/hr of steam at 1575 psia and 900°F.