Page 38 - Chemical Process Equipment - Selection and Design

P. 38

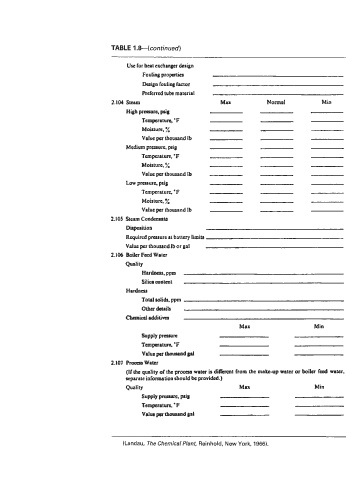

TABLE 1 .&(continued)

Use for beal exchanger Win 2.108 lnat Gas Max Min

Fouling propenia Rcuun. psig

Win fouling factor Derv point. 'F

Preferred tube material Composition

2.104 slerm Mal Noma1 Min Fw cent COz

Hiobpr-%@s Pa ant oxygen

Tanpcratun,'F Fwscntco

Moisture. % Otha vllfe impwitit,

Value per thohourand Ib Quantity avdabk

Medium pressure. pig Value per thousand cu f~

Tcmpaaturc, 'F 2. I09 Plant Air

Moisture. % Supply Source

Vduc per thourand Ib Olirile battery limits (OSBL)

LQW praruc. pa Portabb compraror

Tanpcrature. 'F Roaco air ryrmn

Moistarc. % Special compressor

Vdw per thousand Ib WPlY P-. *s

2 105 Steam Condamre 2.1 IO Innrumart Air

Dirporition Supply IOOYICC (OSBL)

Required pressure at battery limits Special compressor

Vduc per thousand Ib or gal Supply p=u=. prig

ZIW Boii Fd Wata DCW poiot, 'F

Quality Oil. dirr rad moisture removal rtguircmcnts

H-.PP= In general a value of plant and instrument air is usually 001 given aa the yearly over-all

silica Eonlcnt cost is innignikant in dation to the other utilities required.

H.rdncu 3.101 wute Dirpowl Requirrmcnu

Toul did% ppm In @. lhcrc arc thm types of WW to bc conridercd: liquid, solid and gaseous. The

destinatioo and disposal of a& of thop clsuents is wurlly ditracnt. Typical items are u

0th darib rolbws:

chmdcaltiver Dcni~tim of liquid efaucnu

Max Min Cooling water blowdown

SuPPlYP-rc Chanical ICWU

Tanpraturr. 'F

stom tcploI

Vdw per lhourond gal Metbod of chemical lrca~@ for liquid &IS

.

2107 Pmcsrr Watu Relcmdmata*bofaaslmam nror

(If the quality of Ibc proarr watu ia dikt from the make-up water ur boila feed -tu. Cooliq watu blmdown

separate information should be provided.) CharnicnlIcVcr

Quality MPX Min

StOrmnrer

WPIY m e . prit Facilitia for chemical

Tanpcraturc. * F 1-i- far liquid Cffftrnu

Vdur pcr Ihousand gal Facilities lor tralmcnt of-

cmucnu

Solids disposal

-_

(Landau, The Chemical Plant, Reinhold, New York, 1966).