Page 34 - Chemical Process Equipment - Selection and Design

P. 34

1.10. STEAM AND POWER SUPPLY 11

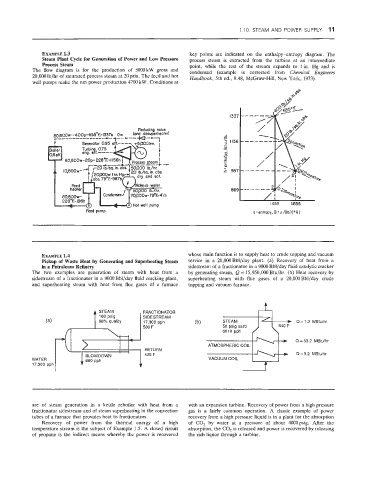

EXAMPLE 1.3 key points are indicated on the enthalpy-entropy diagram. The

Steam Plaint cycle for Generation of Power and LOW Pressure process steam is extracted from the turbine at an intermediate

Process Steam point, while the rest of the stream expands to 1 in. Hg and is

The flow diagram is for the production of 5OOOkW gross and condensed (example is corrected from Chemical Engineers

20,000 lb/hr of saturated process steam at 20 psia. The feed and hot Handbook, 5th ed., 9.48, McGraw-Hill, New York, 1973).

well pumps make the net power production 4700 kW. Conditions at

op”’

‘6

1.618 1.838

Feed pump s =entropy, B.1 u. /(lb.)(DR 1

EXAMPLE 1.4 whose main function is to supply heat to crude topping and vacuum

Pickup of Waste Heat by Generating and Superheating Steam service in a 20,00OBbl/day plant. (a) Recovery of heat from a

h a Petroleum Refinery sidestream of a fractionator in a 9000 Bbl/day fluid catalytic cracker

The two examples are generation of steam with heat from a by generating steam, Q = 15,950,000 Btu/hr. (b) Heat recovery by

sidestream of a fractionator in a 9000 Bbl/day fluid cracking plant, superheating steam with flue gases of a ZO,OOOBbl/day crude

and superheating steam with heat from flue gases of a furnace topping and vacuum furnace.

A

FRACTIONATOR

SIDESTREAM

(4 17,300 pph (b) STEAM Q = 1.2 MBtulhr

580 F

Q = 53.2 MBtulhr

RETURN

425 F Q = 9.2 MBtulhr

WATER VACUUM COIL

17,300 pph

are of steam generation in a kettle reboiler with heat from a with an expansion turbine. Recovery of power from a high pressure

fractionator sidestream and of steam superheating in the convection gas is a fairly common operation. A classic example of power

tubes of a furnace that provides heat to fractionators. recovery from a high pressure liquid is in a plant for the absorption

Recovery of power from the thermal energy of a high of CO, by water at a pressure of about 4000psig. After the

temperature stream is the subject of Example 1.5. A closed circuit absorption, the CO, is released and power is recovered by releasing

of propane is the indirect means whereby the power is recovered the rich liquor through a turbine.