Page 274 - Chemical Process Equipment - Selection and Design

P. 274

9.4. BATCH DRYERS 241

evaporation increases roughly with the 0.8 power of the linear

velocity, high velocities are desirable and are usually achieved by

Materials that require more than a few minutes drying time or are internal recirculation with fans. In order to maintain humidity at

in small quantity are treated on a batch basis. If it is granular, the operable levels, venting and fresh air makeup are provided at rates

material is loaded on trays to a depth of 1-2in. with spaces of of 5-50% of the internal circulation rate. Rates of evaporation of

approximately 3 in. between them. Perforated metal bottoms allow 0.05-0.4 Ib/(hr)(sqft tray area) and steam requirements of

drying from both sides with improved heat transfer. Hot air is 1.5-2.3 lbs/lb evaporation are realized.

blown across or through the trays. Cross velocities of 1000ft/min Drying under vacuum is commonly practiced for sensitive

are feasible if dusting is not a problem. Since the rate of materials. Figure 9.6 shows cross and through circulation tray

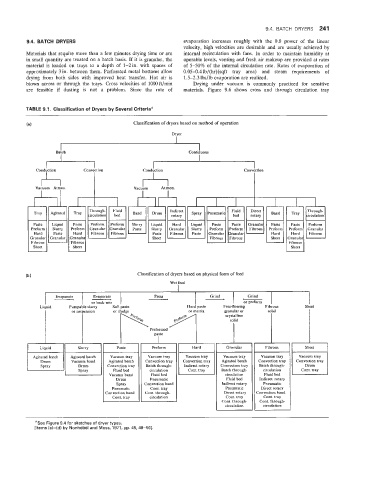

TABLE 9.1. Classification of Dryers by Several Criteriaa

(4 Classification of dryers based on method of operation

Dryer

Conduction Conveclion Conduction Convection

r-l

Vacuum Atmos.

Vacuum Atmos.

Classification of dryers based on physical form of feed

Wet feed

I

Evaporate Evaporate Press Grind Grind

__._ I

I\ crystalline

Pumpable slurry Soft paste Hard paste Free-nowing Fibrous Sheet

or sludne or matrix granular or solid

*,,

K

y, solid

I

Preformed

paste

I

Convection band

eSee Figure 91.4 for sketches of dryer types.

[Items [a)-(d) by Nonhebel and Moss, 1971, pp. 45,48-501.