Page 277 - Chemical Process Equipment - Selection and Design

P. 277

Fan :ers

Dry products

shell chest

Vacuum.

chamber General1 y

Knife steam heated

Steam tube lhot gas) Steam supply

rotary dryer and condensate

Product removal

(9)

Hot gas

Exhaust - s e d t Exhaust

Drive shaft

Loading

Heating Manhole for

jacket dumping and condensate

Agitator

toadmg door

(C)

wet

Cyclone

product

free door Porous dlaphragm

Material aul!et radially on Spider heating lackel support

(d) (i)

I)

Exhaust

Cyclone

Feed -Dryer

Feed

Dry products

I I

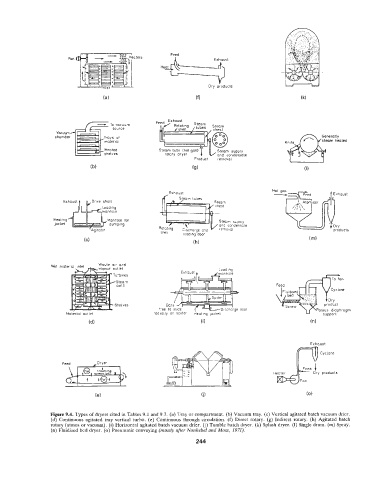

Figure 9.4. Types of dryers cited in Tables 9.1 and 9.2. (a) Tray or compartment. (b) Vacuum tray. (c) Vertical agitated batch vacuum drier.

(d) Continuous agitated tray vertical turbo. (e) Continuous through circulation. (f) Direct rotary. (g) Indirect rotary. (h) Agitated batch

rotary (atmos or vacuum). (i) Horizontal agitated batch vacuum drier. (j) Tumble batch dryer. (k) Splash dryer. (1) Single drum. (m) Spray.

(n) Fluidized bed dryer. (0) Pneumatic conveying (mostly after Nonhebel and Moss, 1971).

244