Page 275 - Chemical Process Equipment - Selection and Design

P. 275

242 DRYERS AND COOLING TOWERS

TABLE 9.1-(continued)

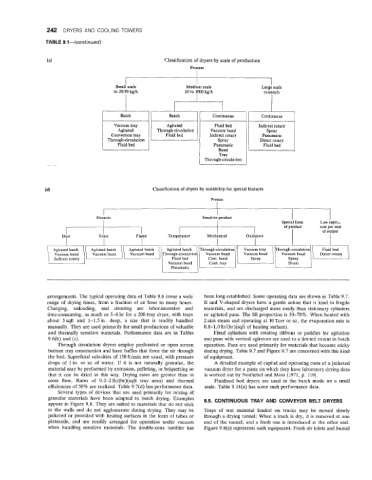

Classification of dryers by scale of production

Process

Smali scale Medium scale Largi scale

to 20/50 kg/h 50 to lo00 kg/h tonnes/h

I I I

Vacuum tray Agitated Fluid bed Indirect rotary

Agitated Through-circulation Vacuum band

Convection tray Fluid bed Indirect rotary Pneumatic

Through-circulation Spray Direct rotary

Fluid bed Pneumatic Fluid bed

Band

Tray

Through-circulation

Classification of dryers by suitability for special features

Hazards Sensitive product

arrangements. The typical operating data of Table 9.6 cover a wide been long established. Some operating data are shown in Table 9.7.

range of drying times, from a fraction of an hour to many hours. It and V-shaped dryers have a gentle action that is kind to fragile

Charging, unloading, and cleaning are labor-intensive and materials, and are discharged more easily than stationary cylinders

time-consuming, as much as 5-6 hr for a 200-tray dryer, with trays or agitated pans. The fill proportion is 50-70%. When heated with

about Ssqft and 1-1.5in. deep, a size that is readily handled 2 atm steam and operating at 10 Torr or so, the evaporation rate is

manually. They are used primarily for small productions of valuable 0.8-1.0 Ib/(hr)(sqft of heating surface).

and thermally sensitive materials. Performance data are in Tables Fixed cylinders with rotating ribbons or paddles for agitation

9.6(b) and (c). and pans with vertical agitators are used to a limited extent in batch

Through circulation dryers employ perforated or open screen operation. Pans are used primarily for materials that become sticky

bottom tray construction and have baffles that force the air through during drying. Table 9.7 and Figure 9.7 are concerned with this kind

the bed. Superficial velocities of 150 ft/min are usual, with pressure of equipment.

drops of lin. or so of water. If it is not naturally granular, the A detailed example of capital and operating costs of a jacketed

material may be preformed by extrusion, pelleting, or briquetting so vacuum dryer for a paste on which they have laboratory drying data

that it can be dried in this way. Drying rates are greater than in is worked out by Nonhebel and Moss (1971, p. 110).

cross flow. Rates of 0.2-2lb/(hr)(sqft tray area) and thermal Fluidized bed dryers are used in the batch mode on a small

efficiencies of 50% are realized. Table 9.7(d) has performance data. scale. Table 9.14(a) has some such performance data.

Several types of devices that are used primarily for mixing of

granular materials have been adapted to batch drying. Examples 9.5. CONTINUOUS TRAY AND CONVEYOR BELT DRYERS

appear in Figure 9.8. They are suited to materials that do not stick

to the walls and do not agglomerate during drying. They may be Trays of wet material loaded on trucks may be moved slowly

jacketed or provided with heating surfaces in the form of tubes or through a drying tunnel: When a truck is dry, it is removed at one

platecoils, and are readily arranged for operation under vacuum end of the tunnel, and a fresh one is introduced at the other end.

when handling sensitive materials. The double-cone tumbler has Figure 9.8(c) represents such equipment. Fresh air inlets and humid