Page 8 - Chemical Process Equipment - Selection and Design

P. 8

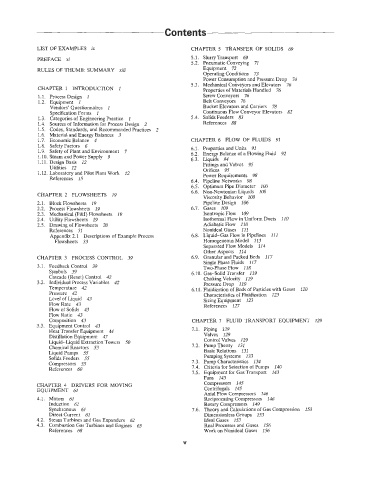

Contents

LIST OF EXAMPLES ix CHAPTER 5 TRANSFER OF SOLIDS 69

PREFACE xi 5.1. Slurry Transport 69

5.2. Pneumatic Conveying 71

RULES OF THUMB: SUMMARY xiii Equipment 72

Operating Conditions 73

Power Consumption and Pressure Drop 74

5.3. Mechanical Conveyors and Elevators 76

CHAPTER 1 INTRODUCTION 1

Properties of Materials Handled 76

1.1. Process Design 1 Screw Conveyors 76

1.2. Equipment I Belt Conveyors 76

Vendors' Questionnaires 1 Bucket Elevators and Carriers 78

Specification Forms 1 Continuous Flow Conveyor Elevators 82

1.3. Categories of Engineering Practice 1 5.4. Solids Feeders 83

1.4. Sources of Information for Process Design 2 References 88

1.5. Codes, Standards, and Recommended Practices 2

1.6. Material and Energy Balances 3

1.7. Econornic Balance 4 CHAPTER 6 FLOW OF FLUIDS 91

1.8. Safety Factors 6

1.9. Safety of Plant and Environment 7 6.1. Properties and Units 91

1.10. Steam and Power Supply 9 6.2. Energy Balance of a Flowing Fluid 92

1.11. Design Basis 12 6.3. Liquids 94

Fittings and Valves 95

Utilities 12

1.12. Laboratory and Pilot Plant Work 12 Orifices 95

References 15 Power Requirements 98

6.4. Pipeline Networks 98

6.5. Optimum Pipe Diameter 100

6.6. Non-Newtonian Liquids 100

CHAPTER 2 FLOWSHEETS 19

Viscosity Behavior 100

2.1. Block Flowsheets 19 Pipeline Design 106

2.2. Process Flowsheets 19 6.7. Gases 109

2.3. Mechanical (P&I) Flowsheets 14' Isentropic Flow 109

2.4. Utility Flowsheets 19 Isothermal Flow in Uniform Ducts 110

2.5. Drawing of Flowsheets 20 Adiabatic Flow 110

References 31 Nonideal Gases 11 2

Appenldix 2.1 Descriptions of Example Process 6.8. Liquid-Gas Flow in Pipelines 111

Flowsheets 33 Homogeneous Model 113

Separated Flow Models 114

Other Aspects 114

CHAPTER 3 PROCESS CONTROL 39 6.9. Granular and Packed Beds 117

Single Phase Fluids 117

3.1. Feedback Control 39 Two-Phase Flow 118

SYnlbOl5 39 6.10. Gas-Solid Transfer 119

Cascade (Reset) Control 42 Choking Velocity 119

3.2. Individual Process Variables 42 Pressure Drop 119

Temperature 42 6.11. Fluidization of Beds of Particles with Gases 120

Pressure 42 Characteristics of Fluidization 123

Level of Liquid 43 Sizing Equipment 123

Flow Rate 43 References 127

Flow of Solids 43

Flow Ratio 43

Composition 43 CHAPTER 7 FLUID TRANSPORT EQUIPMENT 129

3.5. Equipment Control 43

Heat Transfer Equipment 44 7.1. Piping 129

Distillation Equipment 47 Valves 129

Liquid-Liquid Extraction Towers 50 Control Valves 129

Chemical Reactors 53 7.2. PumpTheory 131

Liquid Pumps 55 Basic Relations 131

Solids Feeders 55 Pumping Systems 133

Compressors 55 7.3. Pump Characteristics 134

References 60 7.4. Criteria for Selection of Pumps 140

7.5. Equipment for Gas Transport 143

Fans 143

CHAPTER 4 DRIVERS FOR MOVING Compressors 145

EQUIPMENT 61 Centrifugals 145

Axial Flow Compressors 146

4.1. Motors 61 Reciprocating Compressors 146

Induction 63 Rotary Compressors 149

Synchronous 61 7.6. Theory and Calculations of Gas Compression 153

Direct Current 61 Dimensionless Groups 153

4.2. Steam 'Turbines and Gas Expanders 62 Ideal Gases 153

4.3. Combuetion Gas Turbines and Engines 65 Real Processes and Gases 156

References 68 Work on Nonideal Gases 156