Page 136 - Chemical and process design handbook

P. 136

Speight_Part II_B 11/7/01 3:11 PM Page 2.77

BENZENE 2.77

Extractor Stripper Extract recovery Separator Separator Raffinate

Feedstock

Extract

Raffinate

wash water

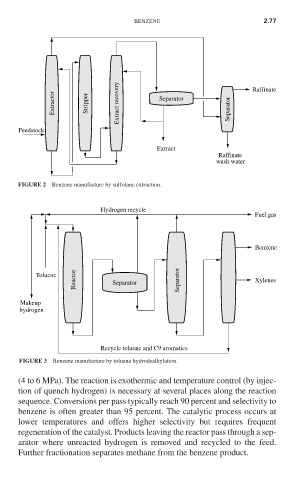

FIGURE 2 Benzene manufacture by sulfolane extraction.

Hydrogen recycle

Fuel gas

Benzene

Reactor Separator Separator Xylenes

Toluene

Makeup

hydrogen

Recycle toluene and C9 aromatics

FIGURE 3 Benzene manufacture by toluene hydrodealkylation.

(4 to 6 MPa). The reaction is exothermic and temperature control (by injec-

tion of quench hydrogen) is necessary at several places along the reaction

sequence. Conversions per pass typically reach 90 percent and selectivity to

benzene is often greater than 95 percent. The catalytic process occurs at

lower temperatures and offers higher selectivity but requires frequent

regeneration of the catalyst. Products leaving the reactor pass through a sep-

arator where unreacted hydrogen is removed and recycled to the feed.

Further fractionation separates methane from the benzene product.